Oct 14 2022

Oct 14 2022

Oct 14 2022

Oct 01 2022

How to make a heater.

No matter in our life or in the factory room we often see, its shape is flexible, widely used.

However, few people can tell the complete and detailed production process of the electric heating tube. I believe that people who have come into contact with the electric heating tube must be very curious about the production process of the electric heating tube.

Preparatory work

1. Treatment of pipe: blanking -- chamfering -- degreasing -- derusting -- cleaning and drying -- brushing pipe -- wiping pipe

2. Processing of electric heating wire: winding wire -- drawing head -- making head

3, the processing of the bar: blanking -- filing teeth -- milling groove -- cleaning

4. Filling material: crushing -- ball grinding -- sieving -- magnetic separation -- drying

The production process of electric heating tube

Thermal-wire connection leading-out rod -- through hollow pipe -- loading powder -- cutting pipe -- annealing -- bending -- welding -- cutting head and surface treatment -- drying -- sealing assembly -- technical inspection

This is the process of producing electric heating tubes, and many of the tubes that we see from the simple ones to the u-shaped ones to the more complicated ones are produced by this process.

1、Blanking and chamfering

Select the pipe material and fixture corresponding to the specification material, determine the size, adjust the positioning block and install the original tube for cutting;

Then, according to the size of the pipe, select the corresponding bit to conduct chamfering on both ends of the pipe;

Finally, put the treated stainless steel tube on the revolving frame and mark the corresponding specifications and models for the next process;

2、Tube straightening

Put the air traffic control tube that needs to be straightened into the straightening machine as shown in the picture. After straightening is completed, tie it with a tie and put it on the turnover truck for the next process.

3、Wipe the tube. Clean

Clean the inner wall of the tube with a tube wiping machine wrapped with white gauze and place the tube behind the wiping tube on the turnover truck for the next step;

4、wire winding

using automatic wire winding machinw,put the finishes resistance wire into the tray and wait for the resistanxe value to be tested.

5、Clean resistance wire and dry.

Add detergent in proportion to clean water, soak the resistance wire for 3 minutes, then rub it repeatedly with your hands for 3-5 minutes, rinse it with clean water and put it on a tray in an oven at 120 ° c, dry it for about 30 minutes to remove moisture.

6、Lead through connection rod, measure resistance

By means of the machine, the lead rod is screwed into the resistance wire, and the resistance value is measured to adjust the screw-in depth. The qualified resistance wire is put into the turnover box to wait for the next process.

7、electric soldering

Welding resistance wire and lead rod with electric welding machine, the welded resistance wire is put into the turnover box to wait for the next working procedure;

8、Fill in the MgO powder

The oscillation delay is set according to the product, which can be adjusted according to the powder density.

Pour magnesium oxide powder into the powder box, start the clamping process, and install the air tube;

Start the thread hanging procedure, install the resistance wire onto the powder adding machine, and check whether the lower plug is pulled in place;

Press the powder adding switch to automatically add powder;

Take out the electric heat pipe after adding the powder, blow or pour off the magnesium powder at the pipe mouth with an air gun for 3 ~ 5mm and then insert the insulation plug to tighten;

Put the electric heat pipe on the testing table to test the withstand voltage as required;

Put the qualified products on the turnover truck for the next process;

9、To reduce the pipe

Open the tube shrinking machine, and then put the lower end of the electric heating tube into the tube shrinking machine mouth to advance slowly;

Testing resistance of electric heat pipe;

Put the qualified electric heat pipe with shrunk tube on the turnover truck and mark the relevant contents such as model and specification, and prepare for the next process;

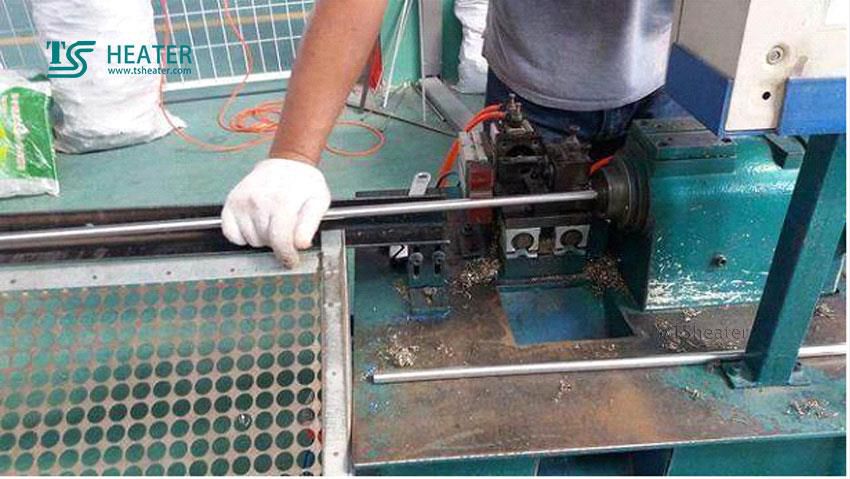

10、Cutting tube

Put the electric heat pipe on the pneumatic bracket, step on the foot switch to cut the pipe automatically and confirm the size;

After cutting, the heating tube is placed on the truck for the next step;

11、Dig powder

Hold the electric heating tube with both hands, insert the rod into the hole of the cutting tool, and push forward slowly.

Put the electrical heat pipe neatly on the turnover truck for the next working procedure;

12.Cutting lead rod

Start the cutting machine switch, hold the handle and slowly press down the redundant length of the cutting rod;

Chamfering is also carried out after cutting, and then the next procedure is prepared;

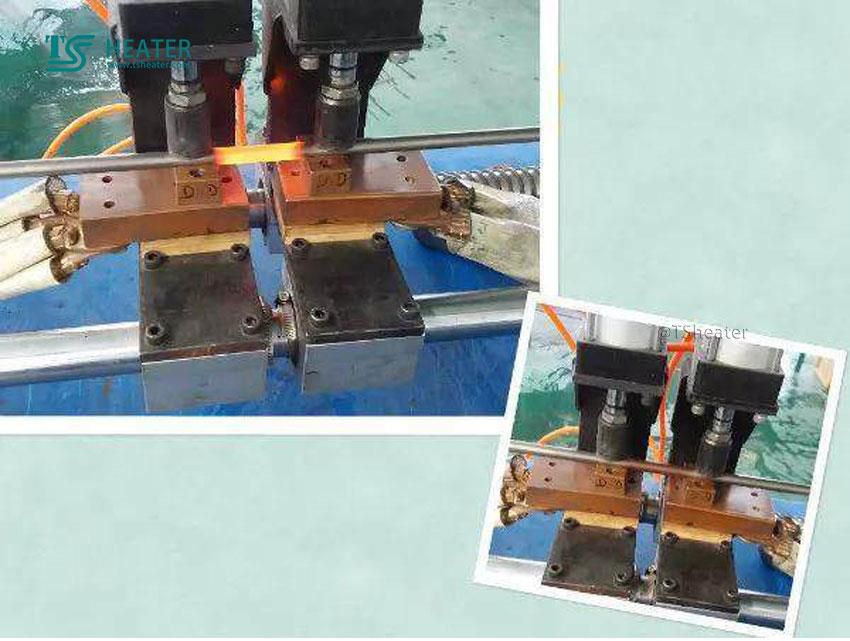

13.selective annealing

The electric heat pipe that needs to be annealed is put into the annealing machine to clamp the copper mold, and one end of the electric heat pipe must be pushed to the positioning module.

Step on the annealing switch to conduct automatic annealing and confirm that there is no melting point on the surface of the pipe after annealing, and whether there is fracture, cracking and other defects in the bending of part R;

Put the qualified products after annealing into the turnover truck for the next process;

14. band tube

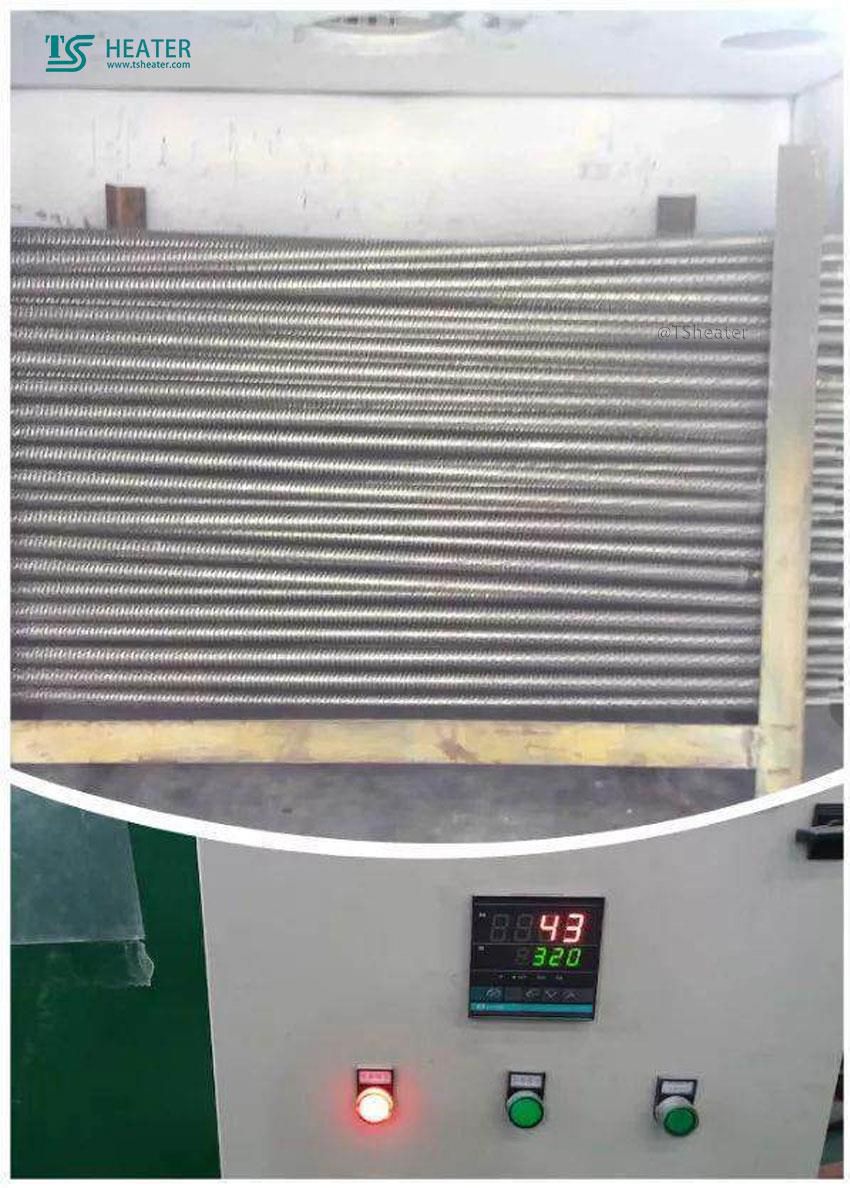

15、Ruled out the moisture

Put the heating tube into the oven, set the temperature and time as required, then start the oven;

After drying, put it in the turnover truck for the next step

16.Glue the seal and lock the nut

Select the appropriate RTV silica gel according to the requirements and point it into the tube mouth, 2mm away from the tube mouth;

Insert the required insulator into the outlet rod, then rotate and insert it into the tube mouth, and wipe off the overflow RTV silica gel around with a cloth.

Install the nut to the heating tube head and prepare for the next step;

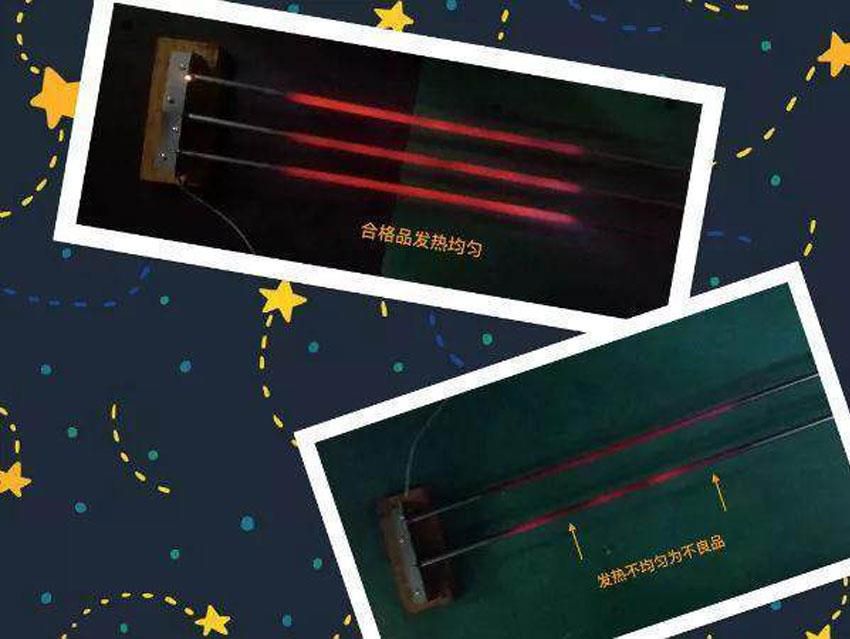

17. Resistance, insulation, voltage test

Use the corresponding testing equipment to test the completed heating tube, qualified products will be carried out the next process;

18. laser marking

19、Examine

Please contact tsheate we can provide raw materials and technical support