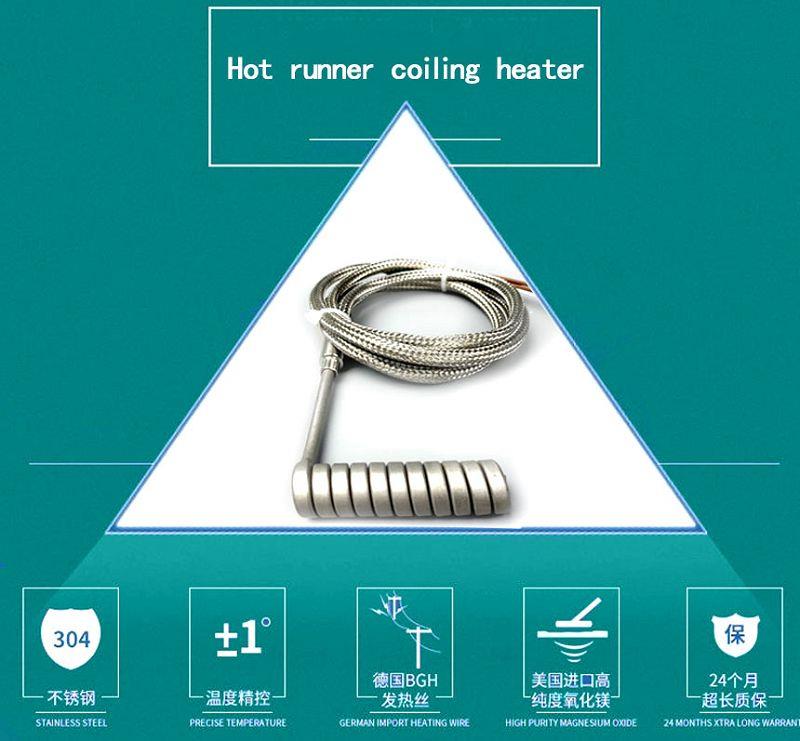

Coil Heater for Plastic Machine is designed to provide maximum service life to difficult applications. This coil heater 4.2x 2.2mm is robust enough to improve heater life in applications such as zinc diecasting.Coil Heater for Plastic Machine

We believe in long term and trusted relationship for hot tub heater element resistance, air finned heater, wago thermocouple terminal block. We insist on creating first-class technology products with incomparable quality and exquisite service to serve global customers with heart. Perfect sales system and first-class after-sales service let us make more friends in the industry and build a solid brand. We continue to innovate and challenge ourselves to be a growing, profitable, globally operating and diversified company. In the future, our company will continue to overcome difficulties, tap potential and constantly update with determination.

The working principle of Coil Heater:

The principle is that when thicker metal is in an alternating magnetic field, the current will be generated due to electromagnetic induction. When the thicker metal generates current, the current will form a spiral flow path inside the metal, so that the heat generated by the current flow is absorbed by the metal itself, which will cause the metal to quickly heat up. This Coil Heater from our factory is suitable for Plastic Machine

Product advantages

1. Coil Heater can be customized, our factory has many production equipment.

2. There are many types of Coil Heater to meet any needs of you

3. The quality of the Coil Heater is guaranteed. We will go through more than three inspections from production to shipment.

4. The price is very favorable.

Precautions:

1. The heating element is allowed to work under the following conditions:

A. It is forbidden in the air relative humidity not more than 95%, no explosive and corrosive gas.

B. The working voltage should not be greater than 1.1 times the rated value, and the enclosure should be equipped with a ground wire.

C. Insulation resistance≥1MΩ Dielectric strength: 2KV/1min.

2. Coil Heater should be well positioned and fixed, and the effective heating area must be completely immersed in liquid or metal solid, and it is strictly forbidden to burn it. When it is found that there is scale or carbon on the surface of the pipe body, it should be cleaned up and used in time, so as not to affect the heat dissipation and shorten the service life.

3. When heating plastics, the operating voltage should be lowered first, and the rated voltage can be increased after the medium is melted.

4. When heating the air, the components should be arranged crosswise and evenly, so that the components have good heat dissipation conditions so that the air flowing through can be fully heated.

5. The wiring part should be placed outside the thermal insulation layer to avoid contact with corrosive, explosive media and moisture; the lead wire should be able to withstand the temperature and heating load of the wiring part for a long time, and excessive force should be avoided when the wiring screws are tightened.

6. The heating element should be stored in a dry place. If the insulation resistance is lower than 1MΩ due to long-term storage, it can be dried in an oven at about 200°C, or the voltage can be reduced and heated until the insulation resistance is restored.

7. The magnesium oxide powder at the outlet end of the Coil Heater avoids the infiltration of pollutants and moisture in place of use to prevent leakage accidents.

Application of Coil Heater

1. Injection molding machine mold heating

2·Plastic Extruder

3·Pipe Forming Machine

4·Pipe Extrusion Machine

5·Industrial Packaging Equipment

TS heater Services

(1) All your questions, e-mail,inquiry etc , will be replied in 24 hours.

(2) We can give you our prices in one hour as long as receiving your detailed drawings.

(3) If you have problems in design or technology, we can also provide you our professional ideas for your reference.

(4) Strong production team and faster delivery.

(5) Technical support to improve your production technology.

We are committed to creating reliable products and improving service quality for customers, and strive to become a leading manufacturer for Industry Plastic Coil Heaters with Thermocouple in the industry. We fulfill relevant economic, legal and social responsibilities. Our products are sold throughout the country and exported to many regions abroad.