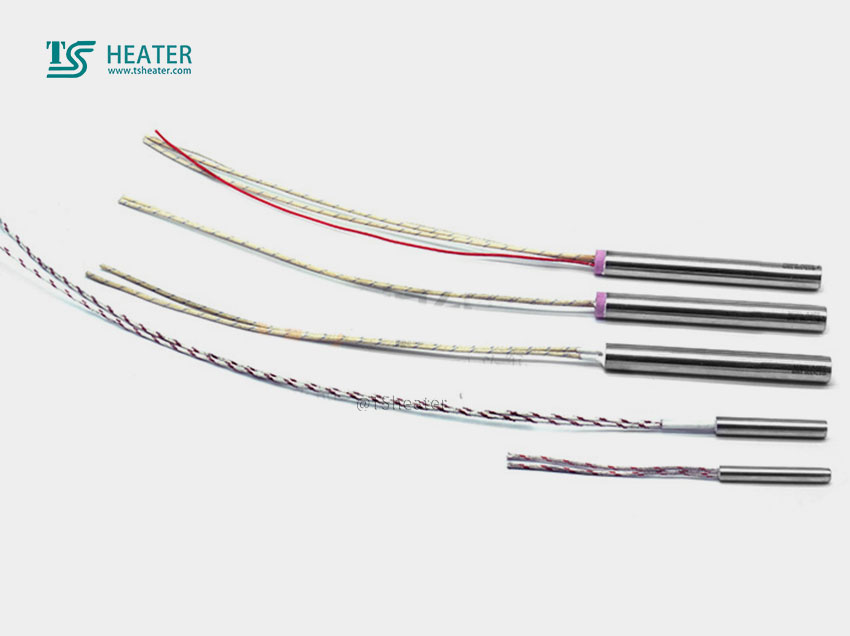

pencil heater.Pencil Heater Resistant Cartridge For Extrusion Machine Pencil Heater It is a versatile and durable product that can be used to heat everything from plastics and packaging applications to critical care medical equipment and analytical testing instruments to various processes used in airplanes, trains and trucks.Pencil Heater

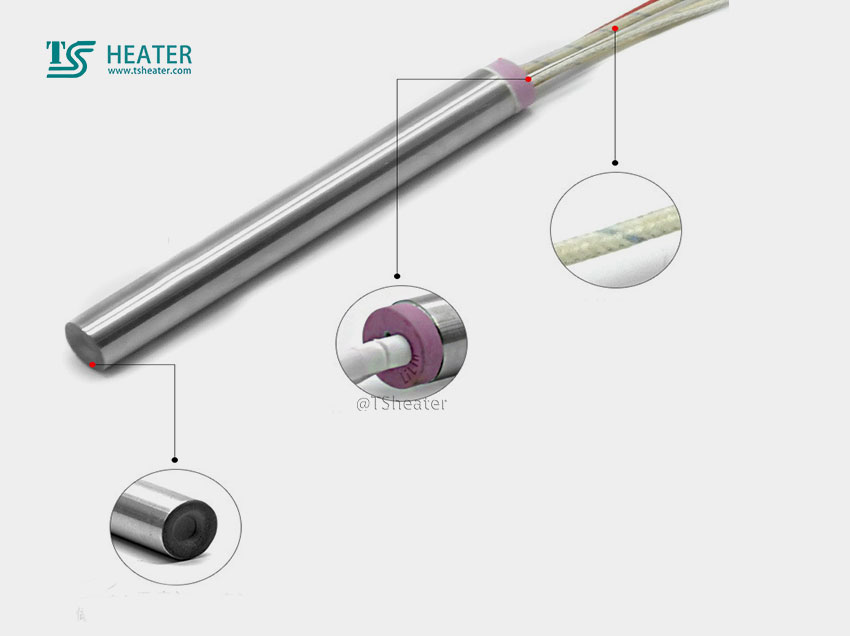

The structure of the drum heater can be divided into six main parts:

1.Heating coil Pencil Heater

The heating coil is the actual resistance, which is where the electrical load occurs.

The most common type of metal alloy used for this purpose is the ni-cr mixture, also known as ni-cr alloy.

The ni-cr wire is wound around the ceramic core and the number of spirals per inch varies according to the required watt density.

The electric potential from the ac source, which may be in phase 2 or phase 3, flows through the coiled ni-cr wire, heating the wire and thus heating the jacket of the drum heater.

2. The insulation Pencil Heater

The insulation is used to protect the ni-cr coil from contact with the sheath, an event that will ground the resistance and may produce a catastrophic short circuit, causing the sheath to melt and major equipment failure.

Damage can be mitigated by installing grounding fault interruption circuits.

To prevent the coil from touching the sheath, the coil is inserted into the sheath and immediately filled with magnesium oxide (MgO).

In order to ensure that the MgO fills the gap between the sheath and the coil, the drum heater is filled in the vibration state.

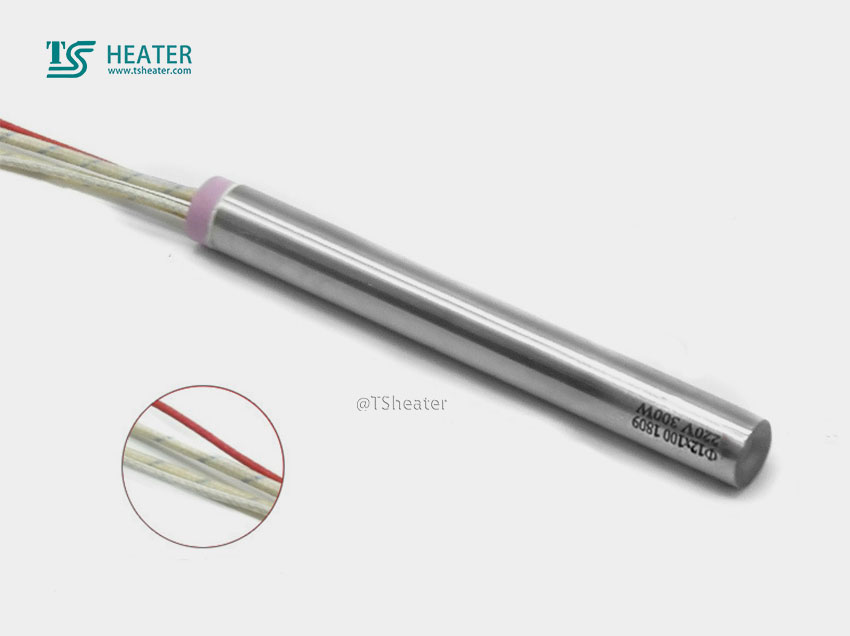

3. The sheath Pencil Heater

The jacket is the part of the cartridge heater in contact with the heated material or substance.

Depending on the type of application, use different metal alloys, such as highly acidic or corrosive environments.

The most common types of sheath are 304 stainless steel, 316 stainless steel and inconel 800.

Mycology has the highest temperature grade and is considered to be a superalloy.

4. The seal Pencil Heater

When the cartridge heater is filled with the MgO, add a seal to the opening end of the cartridge heater (where the ni-cr coil is introduced).

This prevents the coil and MgO from coming out, as well as preventing pollutants such as plastic debris, air, or moisture from entering the heater.

5. Termination Pencil Heater

Since cartridge heaters are installed on a variety of machines, the manufacturer must design the heater to meet a certain gap.

The cartridge heater may te