Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

We focus on the development and design of testing hot water heater element, high temp silicone caps, heat strip bunnings solutions. We rely on scientific business management and strong capital operation capabilities to continuously develop in market competition. Our company adheres to the business philosophy of 'based on professionalism, pioneering and innovative, serving customers, and pursuing excellence' to promote the sustainable and healthy development of the enterprise and provide users with better and more advanced products and services. We take 'the customer's continuous satisfaction is our work standard' as the tenet and take the win-win enterprise culture as the guidance.

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

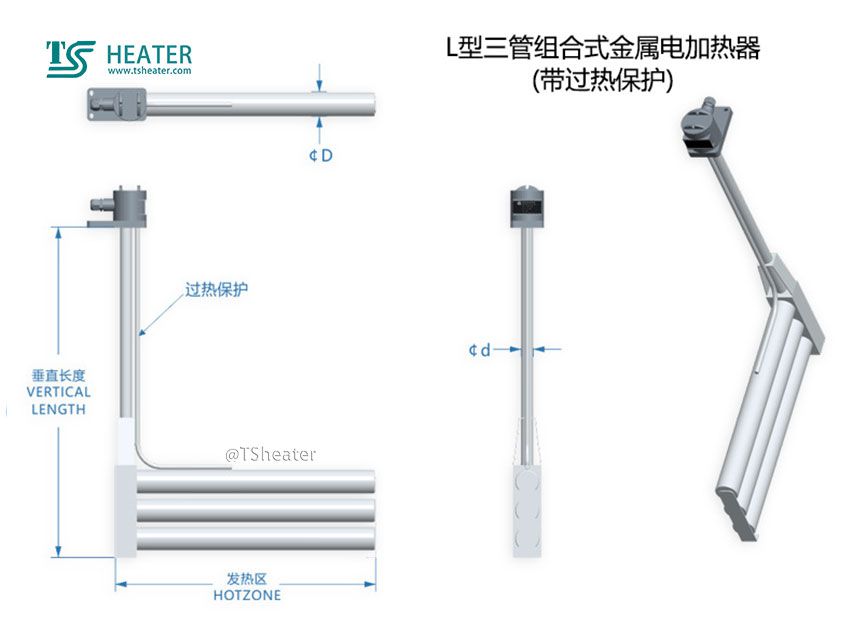

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

We have many years of rich manufacturing experience. We meet the individual needs of customers with advanced design concepts, produce high-quality Sinopts Grill Gas Valve Types Gas Burner Safety Valve for customers and provide comprehensive after-sales services for them. If you have demand, let us work together to get success. All the struggles and efforts of our company are to provide users, upstream and downstream with more thoughtful value-added services.