Submersible Oil Heater,The surface power of the heating tube is 5.6w/cm2, which is suitable for liquid heating with good fluidity, less solid deposition and no crystallization of the liquid on the surface of the electric heater after cooling.

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of hot water tank heating element, high temp electrical wire, micro coil heater. With long-term accumulation of technical strength and well-trained scientific and technical personnel and management team, we provide customers with first-class solutions to create a better future together. With excellent product quality, fast delivery time and perfect after-sales service, our company's products have become the first choice of many merchants and are favored by new and old customers. Welcome customers to come to our company for on-site inspections guidance and business negotiations The company adheres to the principles of customers as our first priority, and makes great effort to increase brand awareness by producing superior products.

1. Titanium, zirconium, SUS304, SUS316 stainless steel tubes are used.

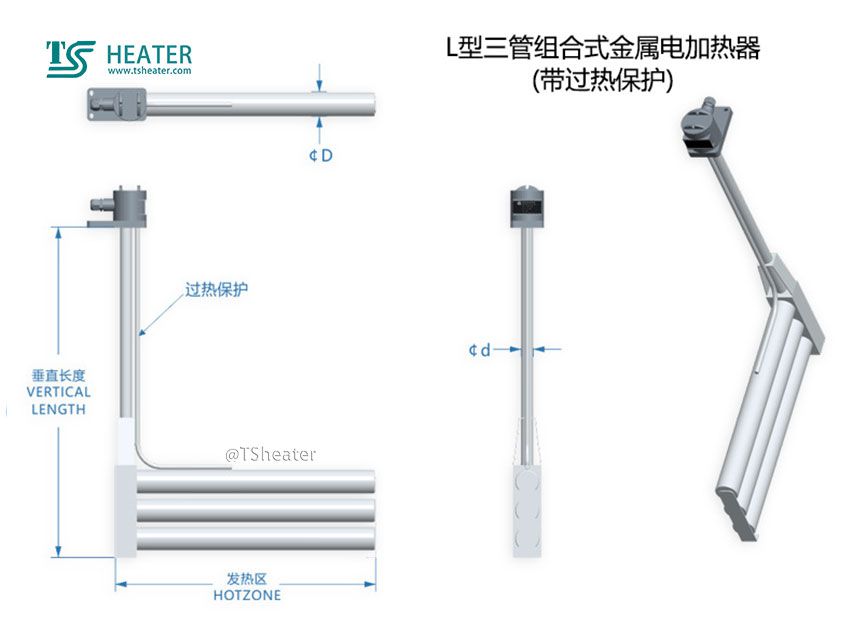

2. Design the surface power of the heating tube and determine the pipe diameter according to the installation location, chemical liquid properties and solid substance deposition characteristics in the liquid. Common specifications for pipe diameter are Ø 11 mm, 17 mm, 25 mm, Ø Ø Ø 30 mm, Ø 32 mm and 45 mm, Ø Ø 50 mm.

3. Submersible Oil Heater, liquid heating, heating tube surface power 5.6 W/cm2, suitable for liquid and solid deposit less, not in the heater surface cooled liquid crystalline liquid heating.

4. 45 mm diameter Ø series of products with low power design surface, good durability, especially for horizontal heating circuit board.

5. The voltage is 120V single-phase, 220V, 380V, 220V three-phase, 380V three-phase, power from 0.5kW to 140KW.

6. All heaters can be equipped with overtemperature protection switch or temperature sensing probe.

7. All heaters adopt international inspection standards to ensure safe electrical performance

Applicable environment: all kinds of electroplating corrosion liquid, due to the difference in steel selection.

Specification design: you can refer to the list of common specifications, or according to customer requirements to design various shapes, specifications, processes, etc.

For details, please consult our engineers and technicians

We carry on to produce and structure top-quality excellent solutions for Sinopts Portable Gas Stove Parts Gas Valve Replacement. Based on the world, adhering to the concept of 'providing cost-effective services for customers', we are highly praised by customers and peers, and have a good reputation. Under the guidance of the corporate principles of fast service, quality assurance, enterprising innovation, and honesty and win-win, we continue to improve service quality and actively strive to increase customer satisfaction.