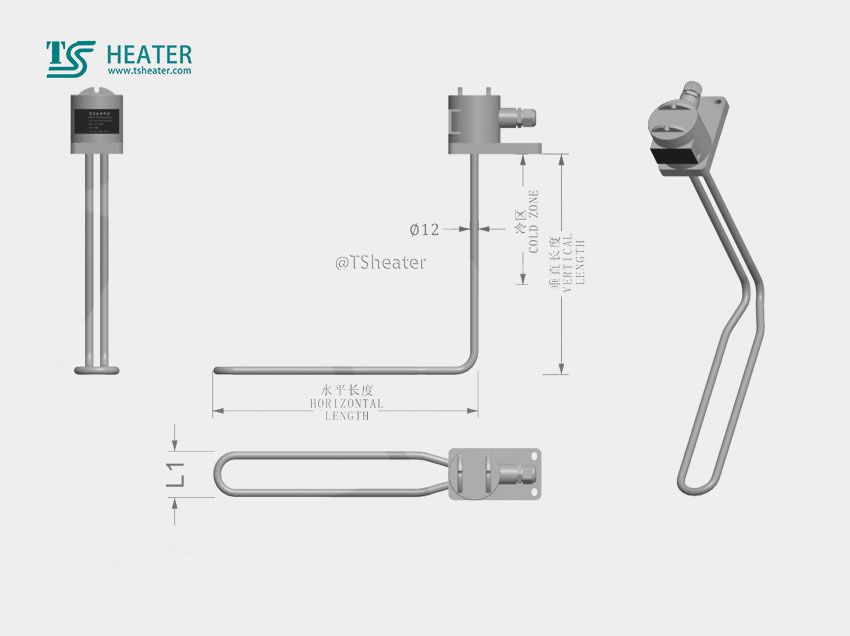

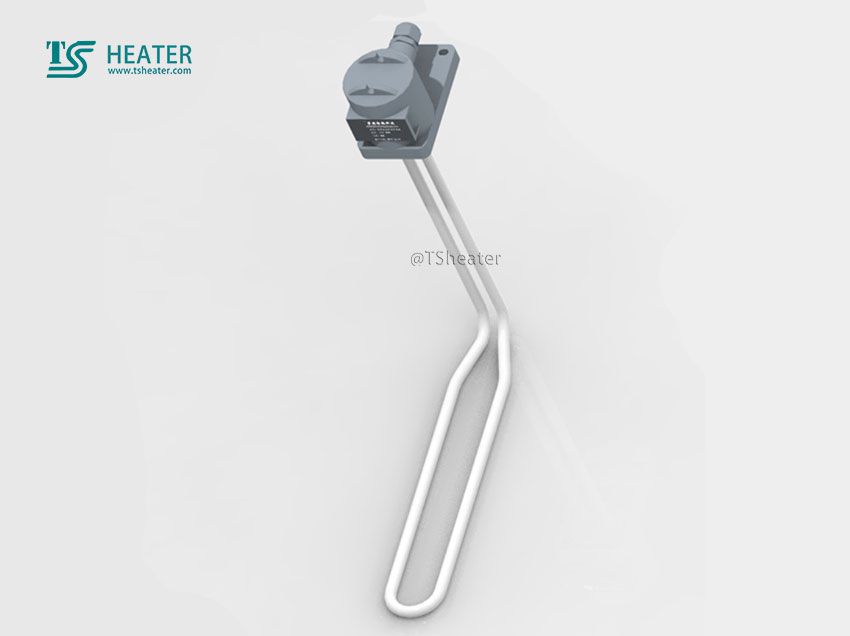

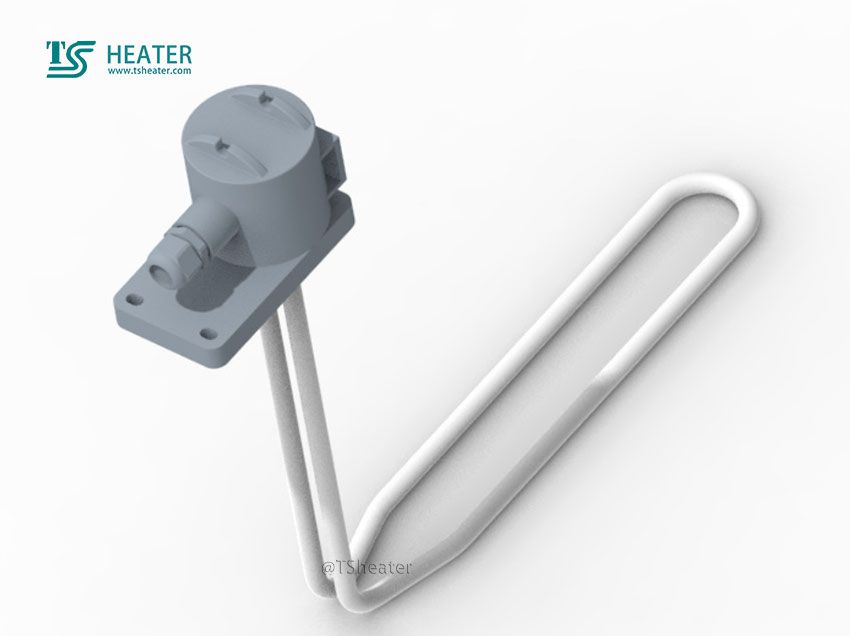

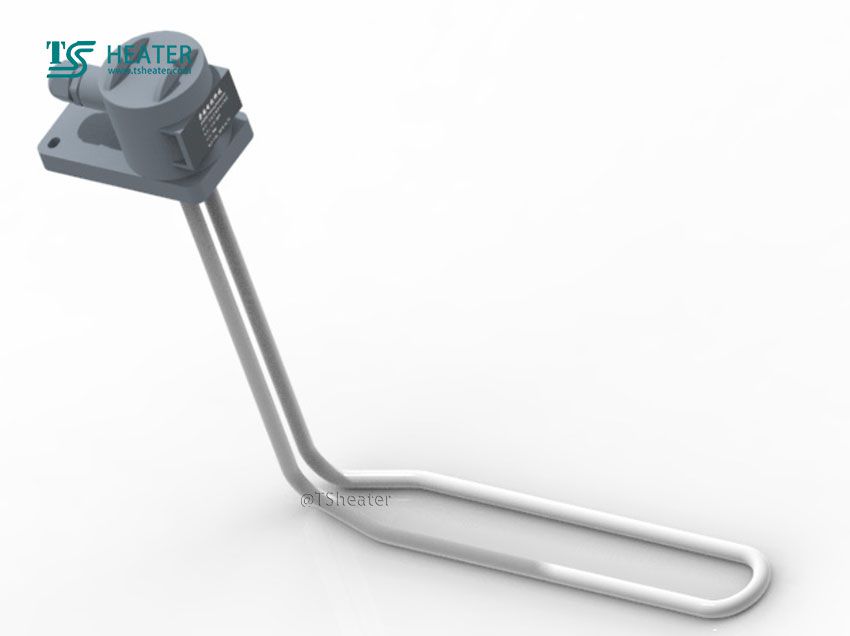

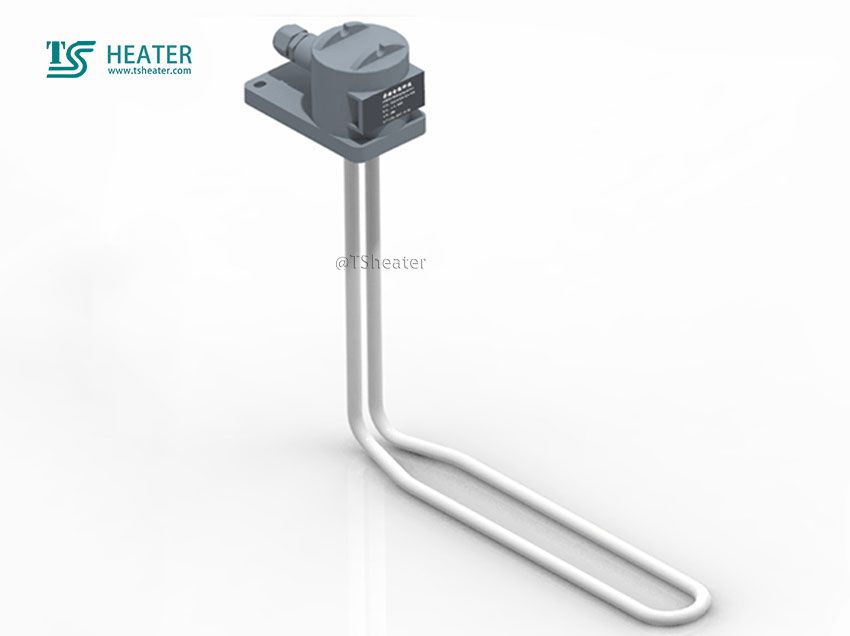

Teflon (PTFE) L Shape Heater,L-type Teflon PTFE tube electric heating tube,can be designed in a variety of structural forms, such as spiral, L-shaped, U-shaped, W-shaped, mosquito-repellent, combined, etc.he installation position of the electric heater should be careful to prevent the solid deposits in the solution from being too thick on the electric heating surface or the liquid is too thick. If the liquid level is too low, the Teflon tube (PTFE) will be burnt due to poor surface heat dissipation.Teflon (PTFE) L Shape Heater

Teflon (PTFE) L Shape Heater

Properties and characteristics of explosion-proof teflon heating tube

Mechanical properties its friction coefficient is very small, only 1/5 of that of polyethylene, which is an important feature of perfluorocarbon surfaces.

And because the fluorine - carbon chain molecular force is very low, so explosion-proof iron - fluorine electric heat pipe is not viscous.

The explosion-proof fe-flon electric heat pipe has excellent mechanical properties in a wide temperature range of -196 ~ 260℃. One of the characteristics of perfluorocarbon polymer is that it is not brittle at low temperature.

Teflon (PTFE) L Shape Heater

Chemical corrosion resistance and weather resistance in addition to the melting of alkali metals, explosion-proof fe-Flon electric heat pipe is almost not corroded by any chemical agents.

For example, in concentrated sulfuric acid, nitric acid, hydrochloric acid, or even boiled in aqua aqua, its weight and performance have no change, and almost insoluble in all solvents, only slightly soluble in all alkanes (about 0.1g / 100g) above 300℃.

Teflon electroplating electric heat pipe moisture absorption, non-combustion, oxygen, uv are very stable, so it has excellent weather resistance.

The dielectric constant and dielectric loss in a wide frequency range are very low, and the breakdown voltage, volume resistivity and arc resistance are high.

The radiation resistance of the flflon electric heat pipe is poor (104 Rads). The degradation is caused by high energy radiation, and the electrical and mechanical properties of the polymer decrease obviously.

The polymerization reaction in the industry of explosion-proof teflon electric heat pipe is stirred in the presence of a large amount of water to disperse the reaction heat and facilitate the control of temperature.

Teflon (PTFE) L Shape Heater

Polymerization generally takes place at 40 ~ 80℃ and 3 ~ 26 kg force/cm 2 pressure. Inorganic persulfate and organic peroxides can be used as initiators, and REDOX initiators can also be used.

171.38kJ/mole of teflon electroplated heat pipe during ethylene polymerization.

The disper

Teflon (PTFE) L Shape Heater