Our factory can manufacture the Ceramic Pad Heating of any specification and size

Our factory can manufacture the Ceramic Pad Heating of any specification and size

The structure of the Ceramic Pad Heating:

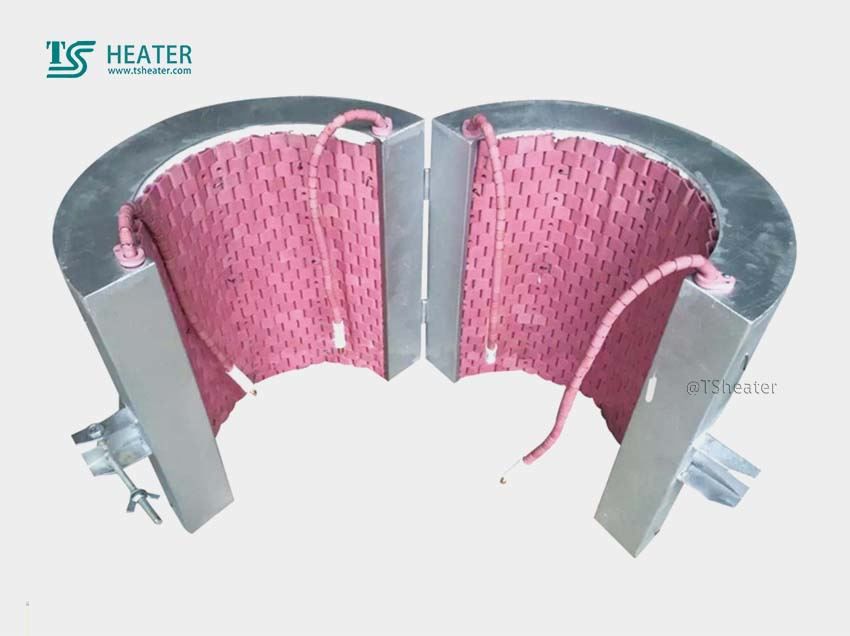

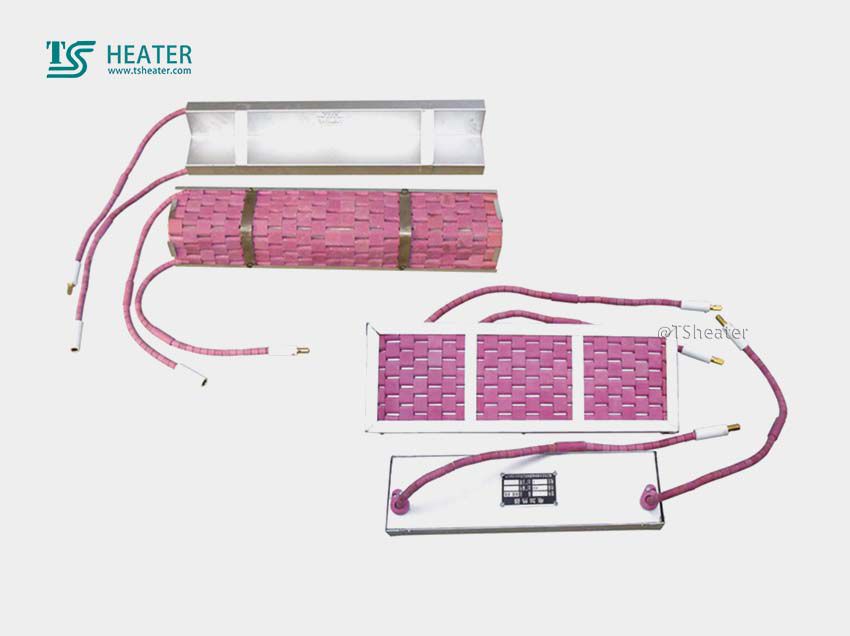

It is made of high-temperature-resistant multi-strand high-quality electric heating wires and high-strength, high-temperature-resistant porcelain pieces spliced according to special process requirements, and has arbitrary bending characteristics in the length direction.

The purpose of the Ceramic Pad Heating:

1) It is widely used for the on-site heat treatment of various industrial equipment and workpieces, drying, heating, and heating of various metal containers and pipes, and high-temperature external heating of various dies and molds.

2) the Ceramic Pad Heating is an ideal product for local heating, field heating, external heating, etc.

Features of the Ceramic Pad Heating:

1. It has winding properties. For example, when heating containers or pipes, it can be bent into an arc or circle to coat the surface for heating. For heating large workpieces, the partial coating can be adopted, and large-area workpieces can be flattened and covered. In addition, it is suitable for heating various geometric shapes.

2. High working temperature, fast heating, high thermal efficiency, no pollution, uniform, and precise heating, and automatic control can be realized.

3. High mechanical strength, good thermal insulation performance, large contact surface with the heated object, and long service life.

4. It is convenient to install and maintain, and the use cost is low. Even if the internal heating material is damaged, the external ceramic components can still be reused.

Technical indicators of the Ceramic Pad Heating:

Dielectric strength: 2000V/1 minute

Thermal insulation resistance: >5MΩ

Maximum working temperature: 1050℃-1300℃ (customized required)

Installation instructions:

1. According to the size of equipment and workpiece, a single component or multiple components can be evenly arranged. The fixing method during installation can be tied with stainless steel wire or bent into a fastening ring, and then fastened in series with screws.

2. In consideration of temperature requirements and energy-saving, the heater should be covered with 6-8cm insulation material and a temperature controller.

3. The heater is not allowed to overlap when in use, so as to avoid the formation of overheated areas and affect life. Be careful not to break the porcelain, so as not to expose the electric heating material and affect safety.

4. The heated workpiece must be reliably grounded. The working voltage shall not exceed 1.05 times the customer rated voltage.

Selection reference for the Ceramic Pad Heating:

Different heating temperature, choose different material resistance wire.

Customization of the Ceramic Pad Heating

If the product has conventional standards, the price is calculated by the meter

If you want to buy customized products, you can choose different materials of resistance wire, please contact customer service when purchasing, thank you.

Parameter table of the Ceramic Pad Heating

| Diameter | Number of Ceramics | Length of Ni-Cr Wire (CM) | Forming Size | Rated Voltage (V) | Rated Power ( KW) |

| 51 | 7*6 | 230 | 185*120 | 28 | 1.25 |

| 57 | 8*6 | 250 | 210*120 | 30 | 1.4 |

| 57 | 8*8 | 270 | 210*160 | 31 | 1.5 |

| 63.5 | 9*7 | 270 | 235*140 | 31 | 1.5 |

| 76 | 10*8 | 370 | 270*170 | 44 | 2 |

| 89 | 12*7 | 370 | 310*190 | 44 | 2 |

| 108 | 14*10 | 610 | 370*210 | 73 | 3.3 |

| 114 | 15*7 | 460 | 390*140 | 55 | 2.5 |

| 133 | 17*13 | 930 | 450*270 | 110 | 5 |

| 159 | 20*11 | 925 | 530*230 | 110 | 5 |

| 168 | 21*10 | 920 | 558*210 | 110 | 5 |

| 219 | 28*16 | 1850 | 720*320 | 220 | 10 |

| 219 | 28*8 | 920 | 720*160 | 110 | 5 |

| 273 | 34*13 | 1850 | 888*270 | 220 | 10 |

| 325 | 40*11 | 1850 | 1050*230 | 220 | 10 |

| 356 | 43*10 | 1850 | 1120*200 | 220 | 10 |

| 406 | 25*18 | 1820 | 650*360 | 220 | 10 |

| 457 | 28*16 | 1850 | 730*320 | 220 | 10 |

| 508 | 32*14 | 1820 | 830*280 | 220 | 10 |

| 568 | 23*19 | 1820 | 600*380 | 220 | 10 |

| 610 | 25*17 | 1820 | 650*340 | 220 | 10 |

| 711 | 30*15 | 1820 | 780*300 | 220 | 10 |

| 813 | 24*18 | 1820 | 625*360 | 220 | 10 |

| 914 | 27*16 | 1820 | 700*320 | 220 | 10 |