Oct 14 2022

Oct 14 2022

Oct 14 2022

Oct 01 2022

Electric heating tube is the general term for all-electric heating tubes. Whether it is heating air, heating liquid, or mold, it can be called an electric heating tube. Then let's take a look at how the electric heating tube is classified?

Introduction and characteristics of the electric heating tube:

Introduction of electric heating tube:

Electric heating tube is made of a seamless metal tube (carbon steel tube, titanium tube, stainless steel tube, copper tube) filled with electric heating wire, the gap part is filled with magnesium oxide powder with good thermal conductivity and insulation and then processed into Various shapes required by users. It has a simple structure, high thermal efficiency, and good mechanical strength. It has good adaptability to harsh environments. The electric heating tube can be used to heat various liquids and acid-base salts, and it is also suitable for heating and melting metals with low melting points.

Features of electric heating tube:

When the electric heating tube is made, the metal electric heating element is used as the heating element. According to the requirements of different heating tube power and voltage, the resistance wire is made into a spring shape with a winding machine, and then the electric heating wire is inserted into the seamless steel pipe, and then The casing is tightly filled with magnesium oxide powder with good insulation and thermal conductivity. Finally, the tube diameter is reduced by a tube shrinking machine. This manufacturing process can not only make the oxide medium dense but also ensure that the heating wire is isolated from the air so that it does not shift in the center position and touch the tube wall. Avoid electrical conduction or uneven heating on the surface of the electric heating tube.

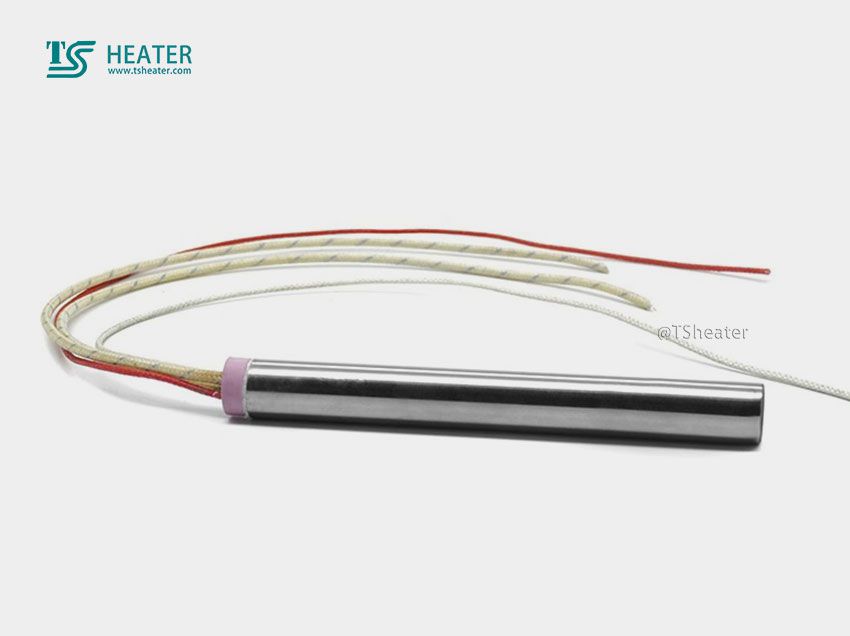

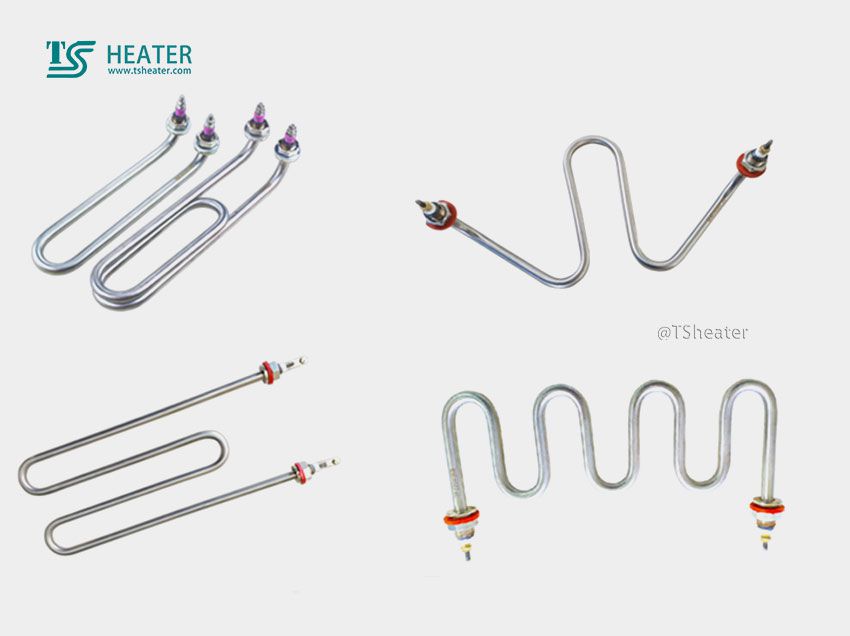

First, we can see from the appearance that the single-ended heating tube is a heating tube with two terminals at one end and sealed at the other end; while the double-ended heating tube is a heating tube with double-ended outlets.

Second, the application range of single-head heating tubes and double-head heating tubes are different. Single-head heating tubes are mainly used in mold heating, plastic packaging, pharmaceutical machinery, laboratory experiments, chemical industry, etc. in modern industries. The double-head heating tube is mainly suitable for heating in the air and uses in liquids, such as closed, circulating air heating, special gas heating, and heating of water, oil, acid, and alkali liquids.

Third, there are also certain differences in the power design of the two. Generally, the surface load of the single-head heating tube is higher than that of the double-head heating tube. Therefore, under the same conditions, the power of the single-head heating tube is larger than that of the double heating tube, and the service life is longer.

Fourth, the characteristics of the two are also different. The diameter of the single-head heating tube is relatively small, at least 3mm; the length is not limited, which can be 20-2000mm; the power can be about 2-5 times that of the normal heating tube; and the structure is simple, the mechanical strength is high, and energy-saving Wait. Double-head heating pipes can be divided into U-shaped heating pipes, double-U flange heating pipes, threaded installation electric heating pipes, double-end fin heating pipes, and double-head waterproof electric heating pipes according to different purposes.

Only by skillfully distinguishing between a single-head heating tube and a double-head heating tube can we better choose the electric heating element that suits you.

If you want to know more about how to classify electric heating tubes, you can contact us online.

Recommended Products:Industrial Immersion Heater,Electric Cartridge Heater,Small Cartridge Heater etc.