heating element coil.Induction hot runner coil heater for Plastic Injection Moulding Machine. Spring heater.China supplier spiral coil heater for hot runner heating element

Heating Element Coil, also known as cable heaters, can be shaped according to their various applications.However, coil heaters are often configured with small diameters and high performance nozzle heaters are fully annealed.The coil heater is used for injection molding machine nozzles and gate bushing to provide 360-degree heat. Optional distributed watt-number models are available.Coil heaters can also be used for cylindrical heaters where holes of irregular size are found.During packaging installation, a straight, round cable heater may wind through the seal strip.

Application of industrial spring heater:Heating Element Coil

1.The manifold

2.Hot runner nozzles and spruce shrubs

3.Packaging machinery

4.Injection molding machine nozzle

Features:Heating Element Coil

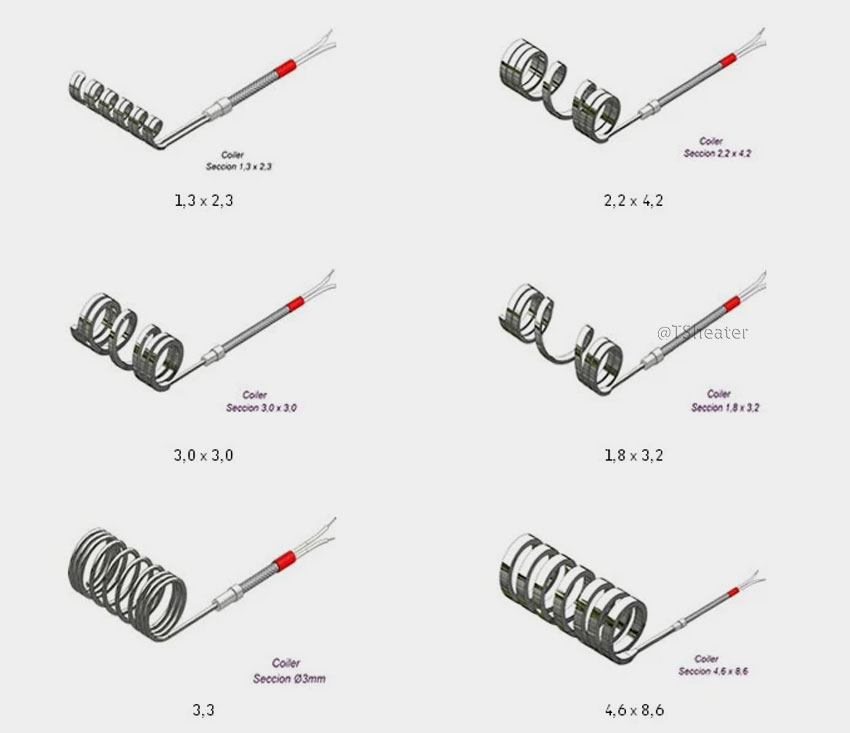

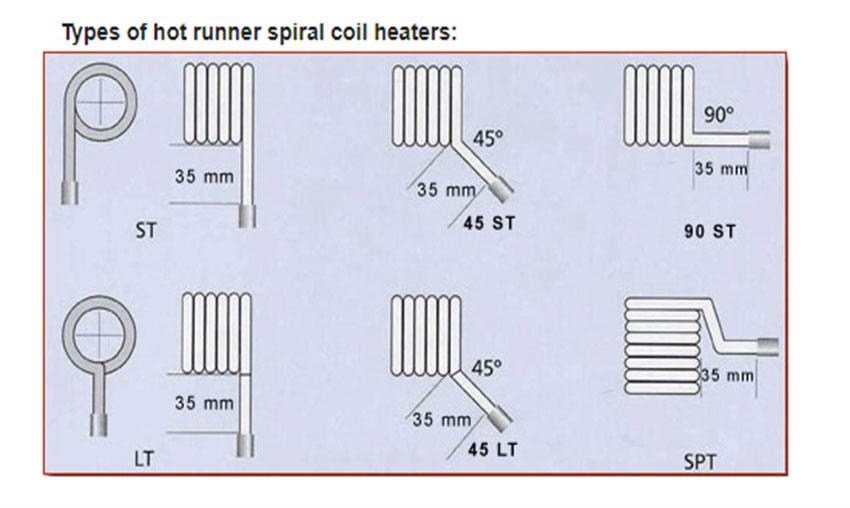

1.Standard dimensions available with various sections

2.Various watt densities are available.

3.Select the robust design of terminal outlet

4.Available with built-in thermocouple

5.Design uniform thermal profiles.

6.Precision mounted on hot runner nozzle and manifold.

7.Highly stainless.

8.Maximum heat transfer due to more contact area.

9.Advanced thermal engineering.

Specifications:Heating Element Coil

Sheath Material:Cr Ni-Steel

Insulation Material:MgO

Resistance Wire: Ni Cr 80-20

Maximum Sheath Temperature :700°C

Voltage: 800V A/C

power > 5 M W

Thermocouple J type (Standard) or K type

Length Tolerance: (Straight) 5%

Wattage Tolerance :+ 10% ( + 5% Available Upon Request)

Resistance Tolerance :+ 10% ( + 5% Available Upon Request)

Unheated Length: 35mm (Standard)

Dimensional Tolerance Coil: ID + 0.1 to 0.2mm

Coil Length: + 1mm

Packaging & ShippingPackaging & Shipping

Packaging & Shipping

-----FACTORY SHOW-----