Variable temperature control is available with the adjustable thermostat with a heating range up to 392ºF. A drum heater is useful for a range of barrel heater options (temperature can vary due to the maximum temperature of liquids).

We uphold a consistent level of professionalism, high quality, credibility and service for k type thermocouple plug, replacing hot water heater element, 55 gallon plastic drum heater. Our company attaches great importance to product quality and regards quality as life. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions.

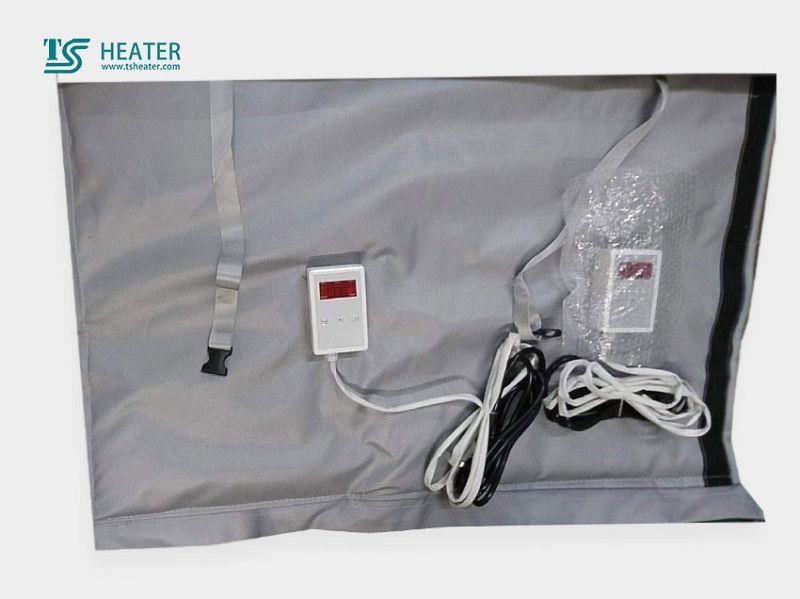

Drum Heater Jacket

Drum heaters are perfect for drums where you want to keep the content at a consistent temperature, a certain viscosity or keeping the content from freezing.

Variable temperature control is available with the adjustable thermostat with a heating range up to 392ºF. A drum heater is useful for a range of barrel heater options (temperature can vary due to the maximum temperature of liquids).

Technical Specifications: Drum Heater Jacket

Thermostat 0-392ºF (0-200ºC)

10 foot power cable

Optimal silicone/glass fabric jacket

High temperature teflon insulated resistance heating wire construction with metal braid

Teflon insulated ground third wire

Insulation: Glass filament materials

Adjustable quick release buckles

Standard sizes.

Thermostat 0-392ºF (0-200ºC)

IP40 approved design

Warm-up duration approx. 28 hours. (55 gallons of water from +60º F to +175º F with a 1200 W drum heater).

The base drum heater may be used additionally

Ideal for heating up: Drum Heater Jacket

Water or oils.

Diesel class fuels.

Wax, e.g. lanolin (wool wax or wool grease).

Suggested use includes using only one drum heater jacket per drum as the heater is designed to be intimate with barrel wall.

The drum heater is designed to perform in applications including industrial liquids made to perform at high temperatures, water, heating oil, diesel fuel preheat, and resin and consistent temperature or viscosity,or materials requiring an optimal preparation temperature prior to usage.

To create more value for customers is our business philosophy; customer growing is our working chase for Heating Jacket for Injection Molding Machine. Guided by customer needs, with the goal of improving production efficiency and quality, we continue to introduce foreign advanced technology to bring customers more comprehensive solutions. Since its establishment, our company has been taking 'quality as the root, management as the foundation, innovation as the way, service as the road' as its purpose, which has won the support and trust of the majority of users and society.