High Density Cartridge Heaters,Great Source Cartridge heateris a piece of equipment, made of MgO powder, MgO tube,ceramic cap,resistance wire(NiCr2080),High temperature leads,seamless stainless steel sheath(304,321,316,800,840).High Density Cartridge Heaters

High Density Cartridge Heaters

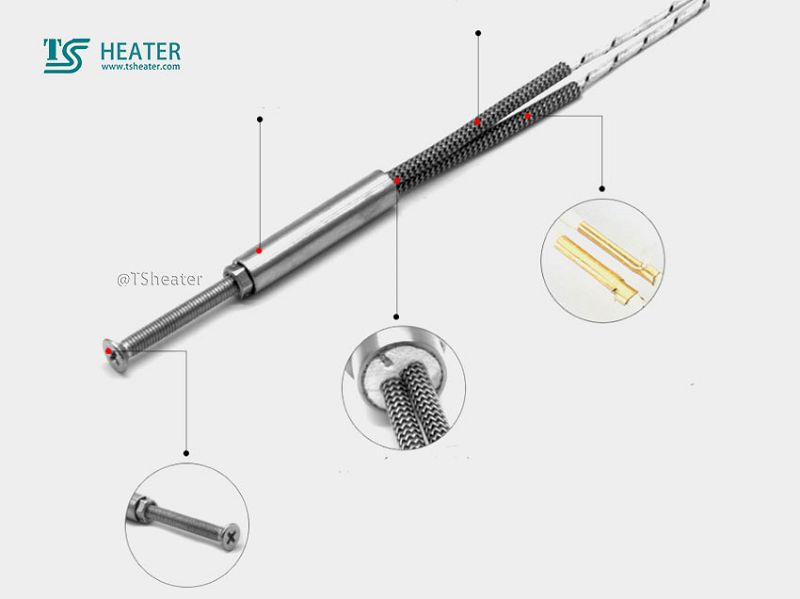

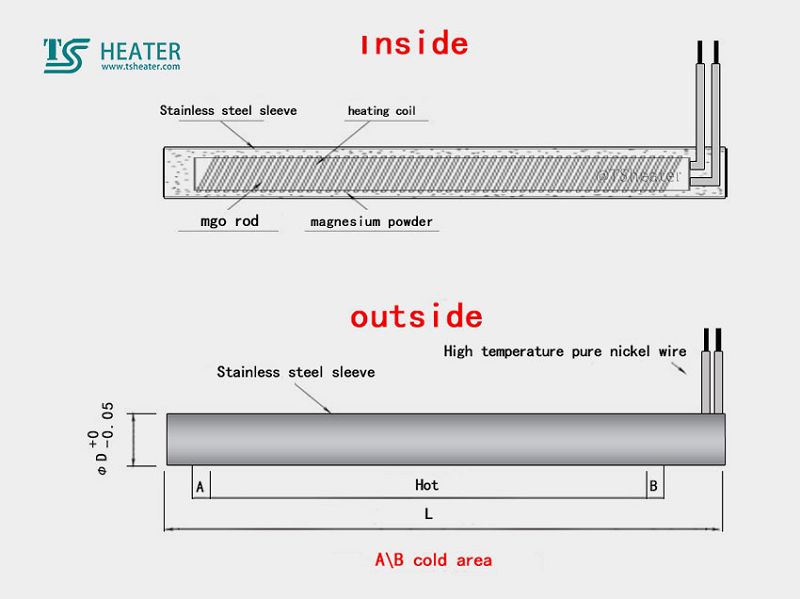

Great Source Cartridge heateris a piece of equipment, made of MgO powder, MgO tube,ceramic cap,resistance wire(NiCr2080),High temperature leads,seamless stainless steel sheath(304,321,316,800,840). All Cartridge Heaters are available with a built in Thermocouple Type J or K.Normally

Features:High Density Cartridge Heaters

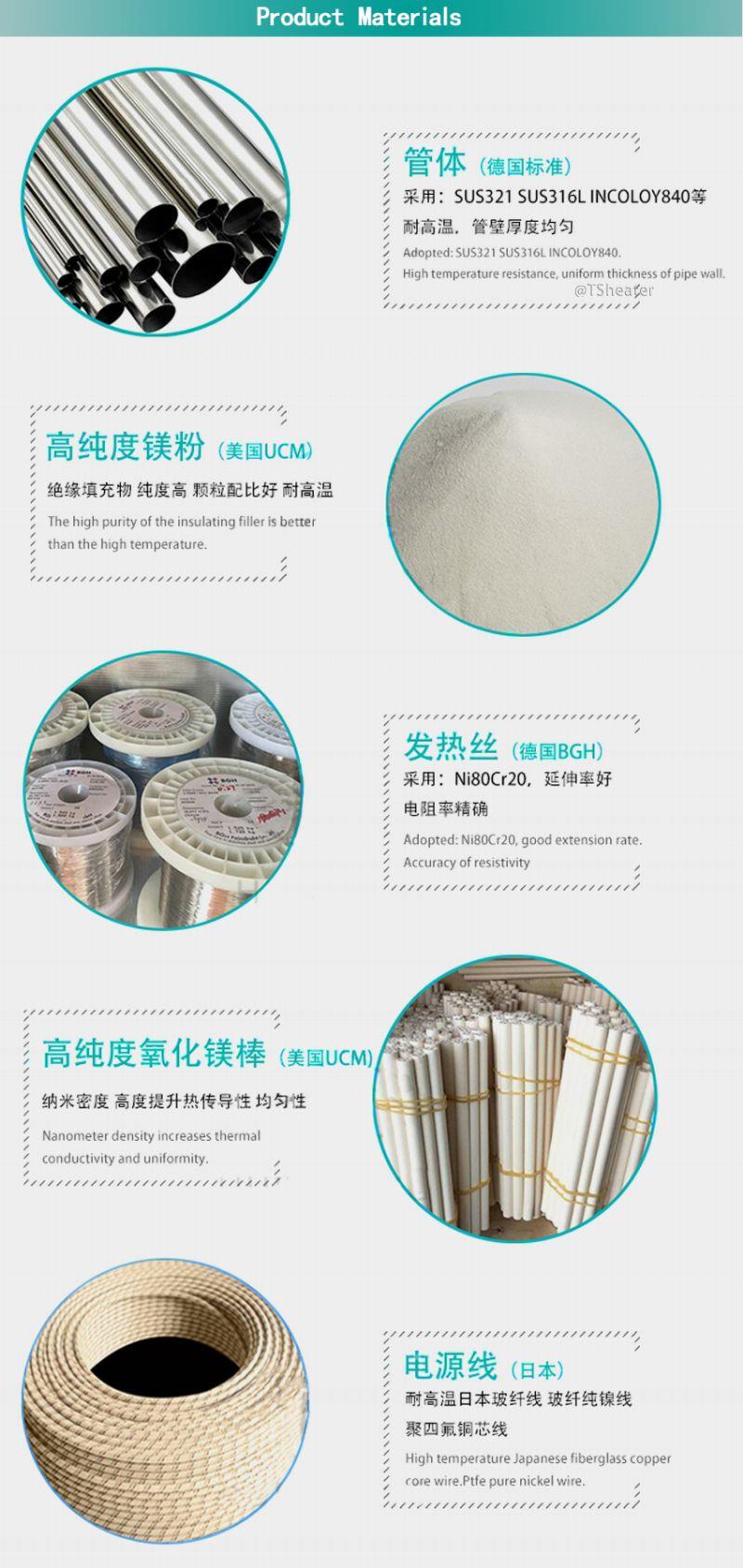

Material SUS304 SUS321 INCOLOY-840 SUS316l SUS310S

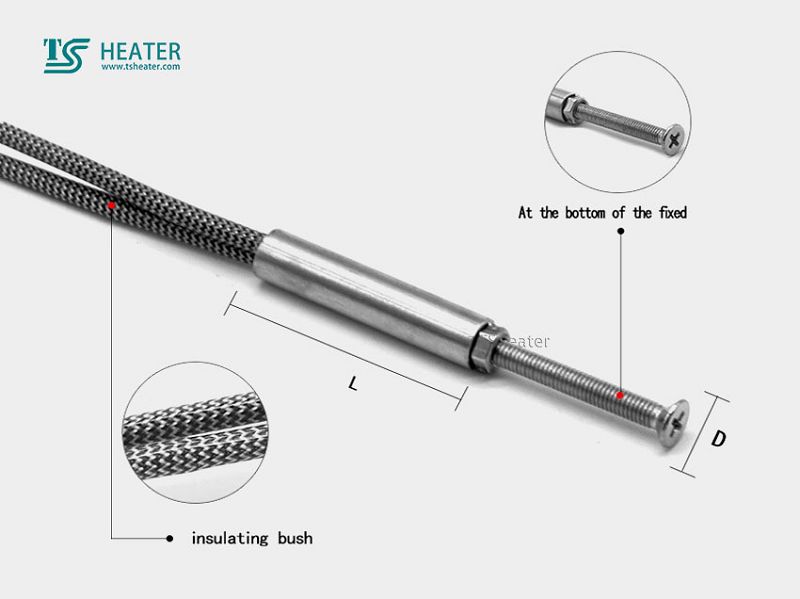

Diameter 2 mm~35mm

Max operating temp 900ºC

voltage 12V-480V or as customer's demand

Heat intensity Not exceeding40Wcm2 (advisable)

Insulation Material Seawater purification magnesium oxide rod, high temperature magnesium oxide powder

Resistance wire element Cr20Ni80

Lead Connection Option Crimped or Swaged leads

Lead and type of connection leads 12" Fiberglass Standard(Wire Options: Silicone /PFA/High Temperature Fiberglass/SS Braided

Cold areas 5-25mm

Internal thermocouple type J,K or E

Thermocouple Location Disc End, Sheath, Center of Heater;

Application: High Density Cartridge Heaters:High Density Cartridge Heaters

Plastic extruders/Plastic molding/Hot runner molds/Shoe machinery/Hot stamping/Food processing/Medical equipment/Heating gases and liquid/Packaging equipment/Glue guns/Molds and dies

Fast heating rate, long service life, no leakage of work

SUS304 or SUS321 seamless stainless steel tube

99% high-purity magnesium oxide rod, Cr20Ni80

nickel fierce material lead-out electrode

External UL certification brand outer fiber copper core wire

Purified seawater magnesium rod and magnesium powder

High density cartridge heaters Raw material including:

1.SS pipe

2.Mgo power

3.Heating wire

4.Mgo rods

5.High temperature cable

6............

Tips for Cartridge Heaters How to Prolong Life Time:

1. Do not exceed recommended maximum watt density specified for the cartridge heater size.

2. The tubular heater sheath must fit properly into the machined hole. A tight fit is critical.

3. Protect the tubular heater from contaminants such as oil, grease, and vapors.

4. Install adequate Kw to accomplish work load and make up for heat losses.