The Right Angle Heating Element Cartridge Heater is a high-load electric heating element, usually used for mold heating. Our company uses imported seamless stainless steel pipes with reasonable internal design. The materials used include high-quality materials, such as high-temperature magnesium oxide rods, oxidation-resistant nickel heating wires, and nickel-manganese lead wires. Fully consider the installation and use environment, and fully control the standardization of pipe diameters. In order to meet customers' requirements for the safety and service life of equipment heating elements.

The Right Angle Heating Element Cartridge Heater is a high-load electric heating element, usually used for mold heating. Our company uses imported seamless stainless steel pipes with reasonable internal design. The materials used include high-quality materials, such as high-temperature magnesium oxide rods, oxidation-resistant nickel heating wires, and nickel-manganese lead wires. Fully consider the installation and use environment, and fully control the standardization of pipe diameters. In order to meet customers' requirements for the safety and service life of equipment heating elements.

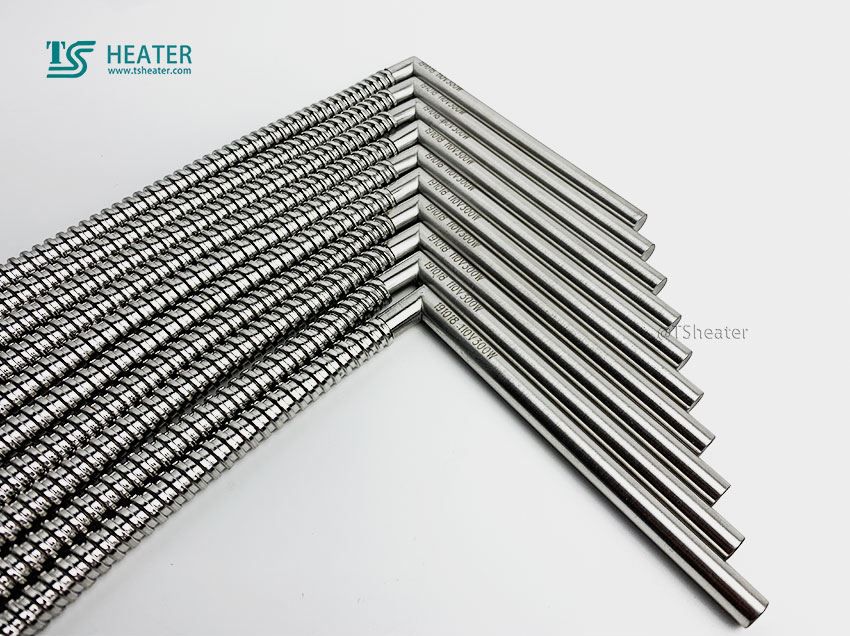

Parameters of the Right Angle Heating Element Cartridge Heater

Pipe diameter: 6-25MM.

The Right Angle Heating Element Cartridge Heater tube material: SUS304 seamless tube.

Electric heating tube hose: all stainless steel (no rubber inside, high-temperature resistance, high-pressure resistance),

Surface treatment: polishing.

Voltage: 110V-440V

Power: 300W (customization can be done within 5000W)

The sealing method of the Right Angle Heating Element Cartridge Heater: glass sealing (RTV).

Electrical performance: Long-term storage insulation value is greater than 50MΩ, the leakage current is less than 0.5mA:

Quality Assurance: One year warranty.

Dimensional tolerance: pipe diameter: ±0.05MM, length: ±0.5MM

Power load: 1W/cm2~17W/cm2

Tube length: 30MM-2500MM.

Outgoing wire: high-temperature wire, terminal, terminal, etc.

Internal heating method: segmentation, soaking, etc.