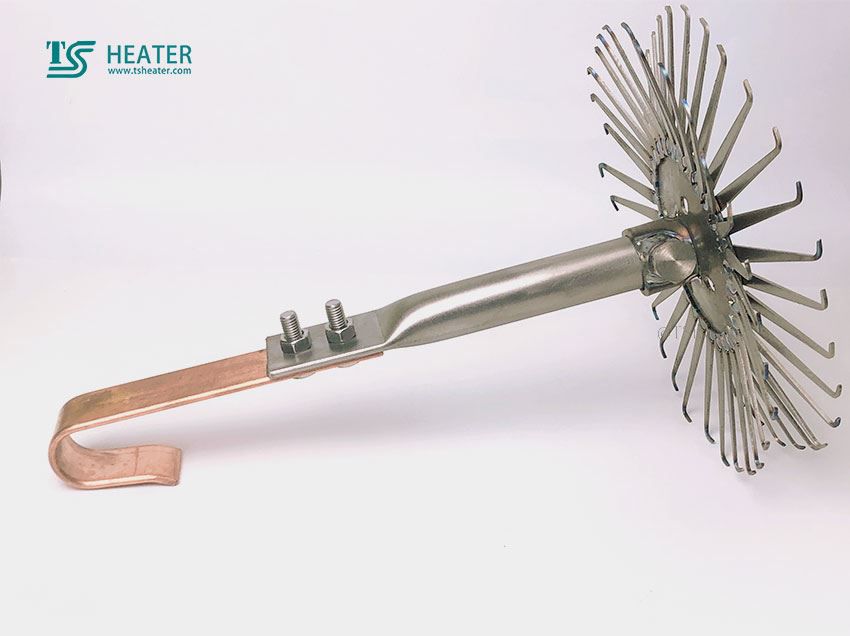

The titanium anodizing rack is made of pure TA2 material, which has good elasticity and strong corrosion resistance. It adopts precision welding technology, and the welding joint is uniform and tight.

Material characteristics

1. Titanium anodizing rack is made of acid-resistant titanium material, and the hook of the contact part of the conductive rod is made of the best copper;

2. It can make the current flow freely without overheating and burning components due to too small cross-section and too large resistance;

3. The contact area with the parts is small, and the contact part will not produce local overheating and burn the parts and components;

4. For those parts that cannot be hung with general-purpose hangers, in order to ensure product quality and improve production efficiency, special hangers can be designed and manufactured according to the appearance and oxidation parts of the parts.

Production specifications:

Teeth: 20, 30, 35, 40 teeth (customizable)

Mesh size: 3mm×6mm 8mm×16mm

Manufacturing state:

Hot-working state (R) Cold working state (Y) Annealing state (M)

Manufacturing process: stamping, rolling, welding

Packing: wooden box or according to customer needs

Our company uses high-quality elastic titanium production, good elasticity, and toughness, acid resistance, alkali corrosion resistance, strong electroplating, suitable for anodizing production lines; high-tech precision welding technology, uniform and tight welds can be designed according to customer needs to be Made! Please contact us, we will give our customers the best service.