Our factory is 100% inspected before packaging. The quality of the Cast Copper Heating Element is no problem.

Parameters of the Cast Copper Heating Element

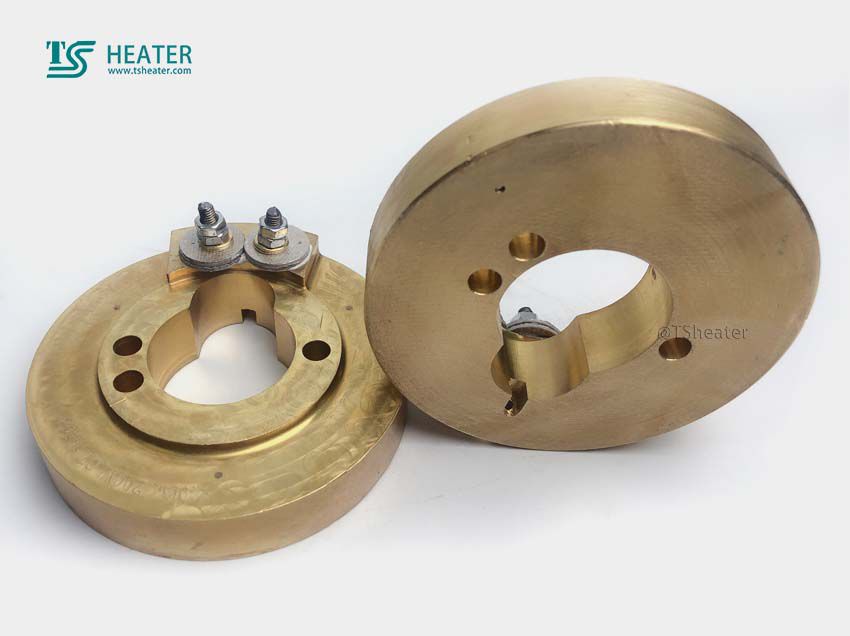

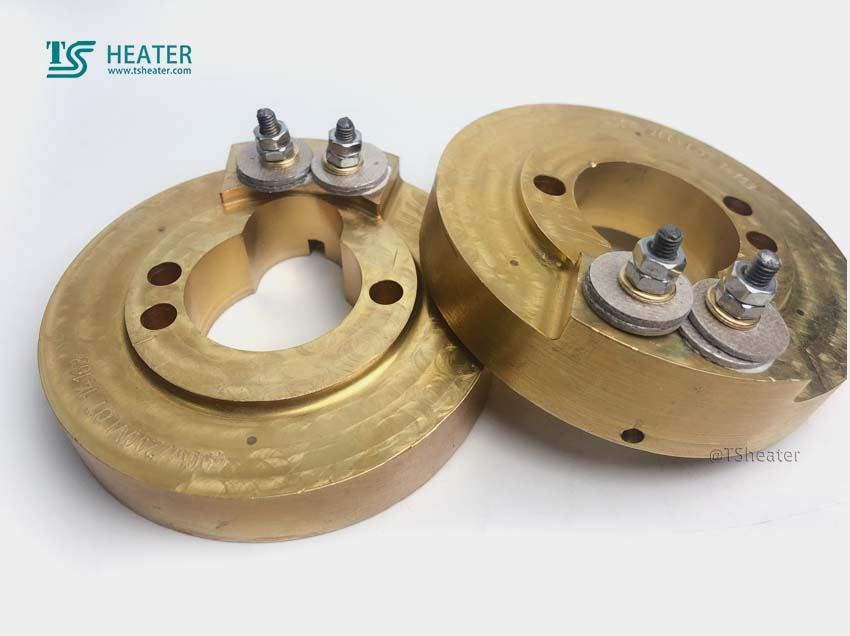

Product Name: Cast Copper Heating Element

Product structure: integrated structure

Heating method: electric heating

Product performance: heat preservation, good mechanical properties

Mode of operation: automation

Working voltage: 220V

Customized processing: design professional solutions according to different requirements of customers.

Precautions for the use of the Cast Copper Heating Element:

1. The working voltage should not exceed 10% of the rated value; the relative humidity of the air should not exceed 95%, and there is no explosive and corrosive gas.

2. The wiring part is placed outside the heating layer and insulation layer, and the shell should be effectively grounded; avoid contact with corrosive, explosive media, and moisture; the lead wire should be able to withstand the temperature and heating load of the wiring part for a long time, and the wiring screws should be tightened. Avoid excessive force.

3. The cast copper heater should be placed in a dry place. If the insulation resistance is lower than 1MΩ due to long-term storage, it can be baked in an oven at about 200 degrees Celsius for 5-6 hours to return to normal. Or reduce the voltage and turn on heating until the insulation resistance is restored.

4. The cast copper heater should be well positioned and fixed, and the effective heating area should be closely attached to the heated body, and empty burning is strictly prohibited. When dust or contaminants are found on the surface, they should be cleaned and reused in time to prevent heat dissipation and shorten the service life.

5. The magnesium oxide powder at the outlet end of the electric heating tube should avoid the infiltration of pollutants and moisture in place of use to prevent leakage accidents.

6. Power: Our factory produces 4.0-6.0W per square centimeter.

Technical characteristics of the Cast Copper Heating Element:

The Cast Copper Heating Element is a tubular electric heating element as heating element, which is bent and formed. The metal alloy material used in the mold is used as the shell and centrifugally cast into various shapes, including round, flat, right-angle, air-cooled, water-cooled, and others Shaped and so on. After finishing, it can fit closely with the heated body,

1) The surface load of cast aluminum can reach 2.5-4.5w/cm2, and the working temperature is between 400-500℃;

2) The surface load of cast copper can reach 3.5-5.0w/cm2, and the working temperature is between 600-700℃;

3) The surface load of cast iron can reach 4.5-6.0w/cm2, and the working temperature is between 800-850℃.

The Cast Copper Heating Element is a heater with uniform heat distribution, and a metal alloy with good thermal conductivity to ensure uniform temperature on the hot surface and eliminate hot and cold spots in the equipment. It has the advantages of long life, good heat preservation performance, strong mechanical properties, corrosion resistance, and magnetic field resistance. Adding heat preservation devices to the outer heat dissipation surface and sintering infrared rays on the inner heat dissipation surface can save electricity by 35%.

The main purpose:

1) Plastic machinery,

2) Mould

3) Cable machinery

4) Alloy die casting machine

5) Pipeline

6) Chemical

7) Rubber

8) Petroleum and other equipment.

Our factory technical requirements and factory inspection standards:

1) Leakage current: The leakage current of the component under working temperature and after the sealing test of the hydraulic testing machine should not exceed 0.5mA (other counterparts should not exceed 0.75mA)

2) Rated power deviation: +5%/-10%

3) Insulation test: 1000MΩ (other peers generally only have 100MΩ)

4) Breakdown test: 2000V/s (other peers generally only have 1300V/s)

5) Life test: batch inspection, the heating element is used at the frequency provided by the customer. 6) The normal working life is not less than 3000h. Or use the rapid life test method proposed by the French SEB company and the Swedish Kangta company.

6) Water pressure test: components used for liquid heating and whose joints are installed below the liquid surface. If flanges are welded, they should be able to withstand a water immersion pressure test of 1.2 MPa for 5 minutes, and there will be no leakage after the test; The fastening device should be able to withstand a water immersion test of 0.3 MPa for 5 minutes without leakage after the test.

7) Except for the live test in Article 5, which is a random inspection for the above test items, our factory performs 100% inspection before packaging.

The display of the Cast Copper Heating Element: (The photo has color difference)