Customized Teflon Immersion Heater,Heater material can be used for PTFE (fluoropolymer): thick-walled fluoropolymer (PTFE) covered stainless steel elements, reducing the need for penetration and eliminating the need for gas purification systems.Customized Teflon Immersion Heater

Customized Teflon Immersion Heater,

Characteristics of the

1) excellent chemical resistance: suitable for various acid, alkali, anodic oxidation and pickling solutions

(2).Heater material can be used for PTFE (fluoropolymer): thick-walled fluoropolymer (PTFE) covered stainless steel elements, reducing the need for penetration and eliminating the need for gas purification systems.

Guarantee 100% without pinhole.

(3).Long service life: low-watt density design (10 watts several inches, 1.5 w/cm2)

Long service life.Customized Teflon Immersion Heater

(4).PVC resistance heater head

(5).Safety grounding and thermal protection:

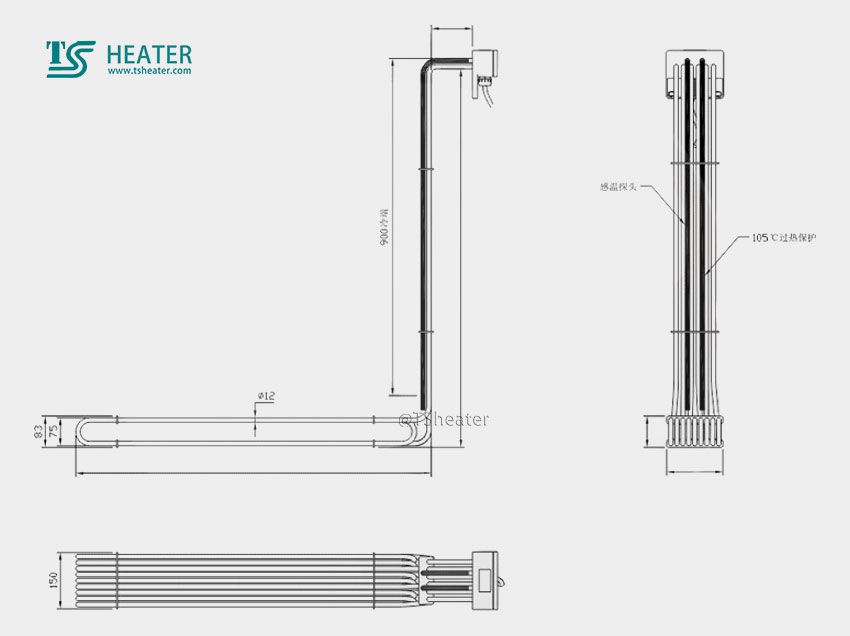

Replaceable heat protectors range from 80°C to 105°C.

(6).Power: from 0.5KW to 9KW

(7).Voltage :120-600 volts, sound phase only

We have custom-made heaters that can be manufactured in any watt, voltage size according to the customer's requirements

We recommend this immersion heater for temperature control and level control.

Application:Industrial heating process

Customized Teflon Immersion Heater

If Q is positive, it is the heat required to heat up

Where Q is negative, is the amount of cooling required for cooling

T: Heating or precooling time H (hours)

Electrothermal equivalent (electrolytic heat)

Q = 0.864×I×V (Kcal/h)

I: Total current A V: slot voltage V

Determination of heat transfer area S of electric heat exchanger

S = Q/K * Δ T * T

Q: Heat exchange (kilocalories)

K: Heat transfer coefficient KCAL /m2× HR ×℃(see Heat transfer coefficient Table V)

V: Solution volume (liter)

Δ T: the average temperature difference

T: Set heating (cooling) time (h)