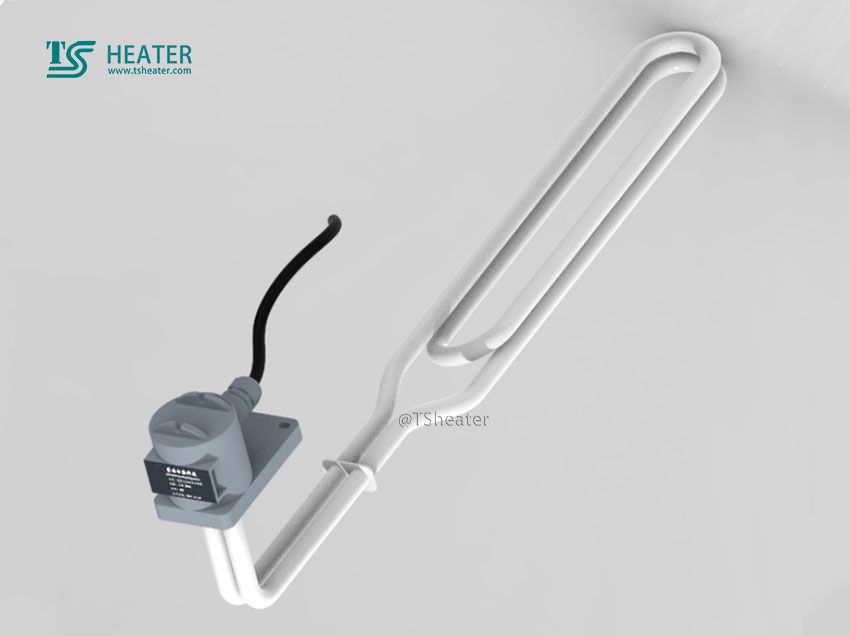

PTFE Teflon coated immersion heater,PTFE heating tube/heating tube are designed with low surface power of 1.5w /Cm2 to ensure the service life of the heating tube/heating tube;PTFE Teflon Coated Immersion Heater,PTFE Teflon Coated Immersion Heater

Description of explosion-proof teflon electric heating tube

1. It has strong chemical corrosion resistance and can be used for heating highly destructive liquid.

2. The heating tube in the teflon electric heater is made of special metal with the coat of PFA.

3. Teflon electric heater can be adapted to PT-100, temperature fuse and temperature switch.

4. During use, the surface of teflon tube is not allowed to be bruised or scratched.

Ii. Description of explosion-proof teflon electric heating tube

1. The inner core of special stainless steel high quality metal electric heat pipe is made by PTFE, which is resistant to corrosion and suitable for heating all kinds of corrosive liquids.

2. Low surface power design (1.5W/CM2) to ensure the service life of the product.

3. The installation position of the electric heater should be careful to prevent the solid in the solution from deposition on the surface of the electric heater, or if the liquid is not thick and the liquid level is too low, the teflon tube (PTFE) will be burnt due to poor surface heat dissipation.

4. The volume size of the electric heater should not be changed to a small surface area, otherwise the surface power of the electric heater will be too large, affecting the service life of the electric heater.

5. All heaters can be equipped with overheat protector or PT100 temperature sensor probe to ensure product service life and equipment safety.

6. Because of the strong corrosion resistance of PTFE (PTFE) pipe is too non-viscous, it is widely used in trioxide polishing, chemical gold plating, chemical nickel plating and heating of various highly-required liquid medicines.

7. Various structural forms can be designed, such as spiral, L, U, W, mosquito-repellent incense and combination.

Three, explosion-proof teflon electric heating tube selection

The choice of explosion-proof teflon electric heating tube

According to the requirements of different processes to choose different materials.

Such as poly four electric heater, has excellent heat resistance (long-term use temperature minus 250℃ to 260℃), strong acid corrosion resistance, not easy to scale (almost all viscosity can not adhere to its surface, so it is widely used in the surface treatment industry).

The intelligent temperature control system can control the process temperature at 1℃ or so.

Automatic control of setting temperature rise, heat preservation and temperature drop. Digital display of high and low temperature alarm is intuitive.

Selection on the basis of

1. Tank internal size, length X height X width, liquid level height.

2. Process temperature, starting temperature and termination temperature.

3. Heating or cooling time required by the process (h).

Exchange heat (heating, cooling)

Q = V×C× R × (T2-T1)/T (kcal)

V: Solution volume (liter)

C: Specific heat of solution (kcal/l ×℃)

R: Specific gravity (kg/l)

T1: Initial temperature of solution

T2: Solution termination temperature

: Coefficient of heat loss (1.10-1.30)

If Q is positive, it is the heat required to heat up

Where Q is negative, is the amount of cooling required for cooling

T: Heating or precooling time H (hours)

Electrothermal equivalent (electrolytic heat)

Q = 0.864×I×V (Kcal/h)

I: Total current A V: slot voltage V

Determination of heat transfer area S of electric heat exchanger

S = Q/K * Δ T * T

Q: Heat exchange (kilocalories)

K: Heat transfer coefficient KCAL /m2× HR ×℃(see Heat transfer coefficient Table V)

V: Solution volume (liter)

Δ T: the average temperature difference

T: Set heating (cooling) time (h)