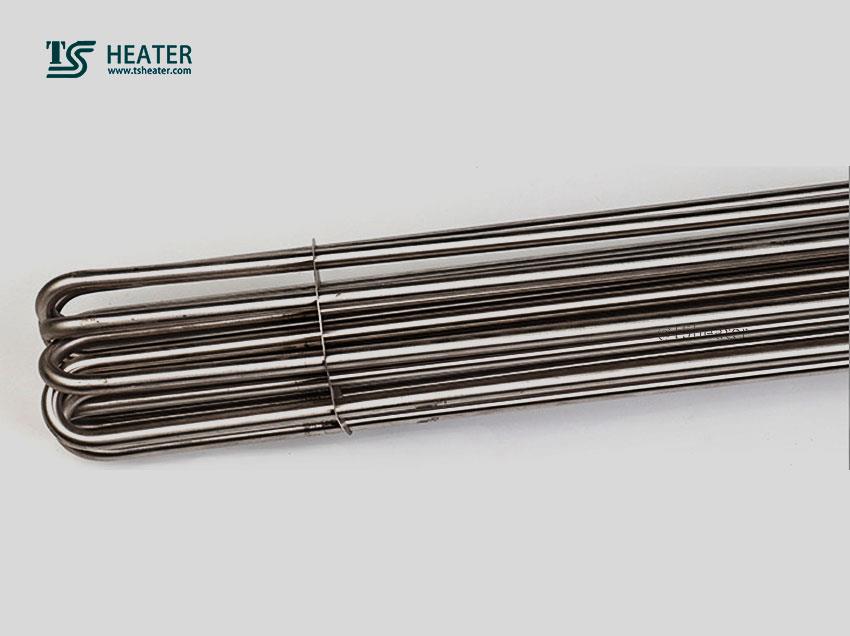

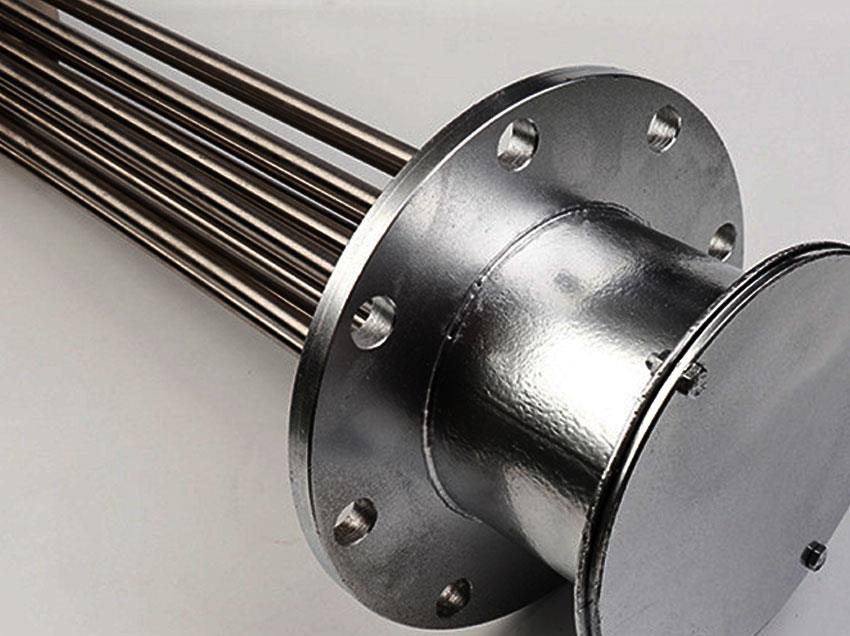

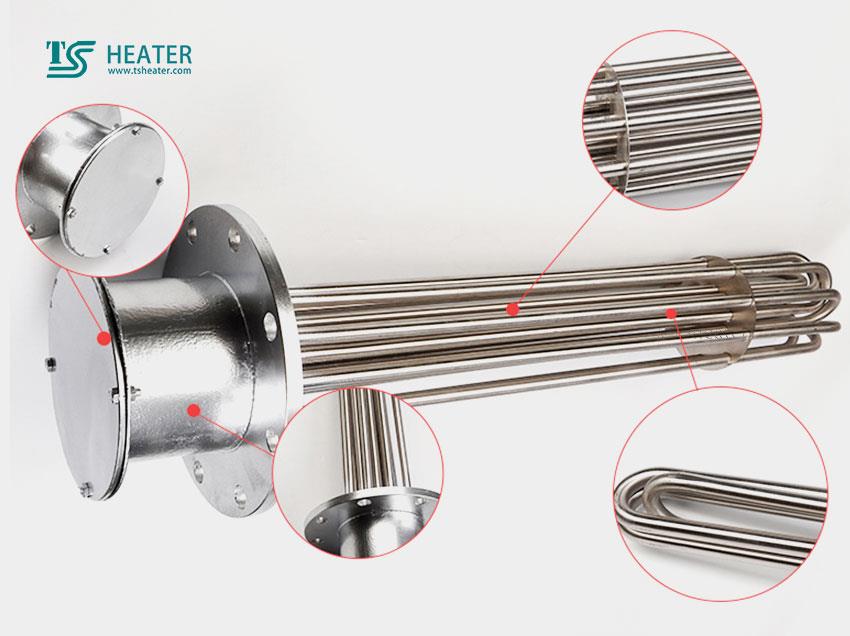

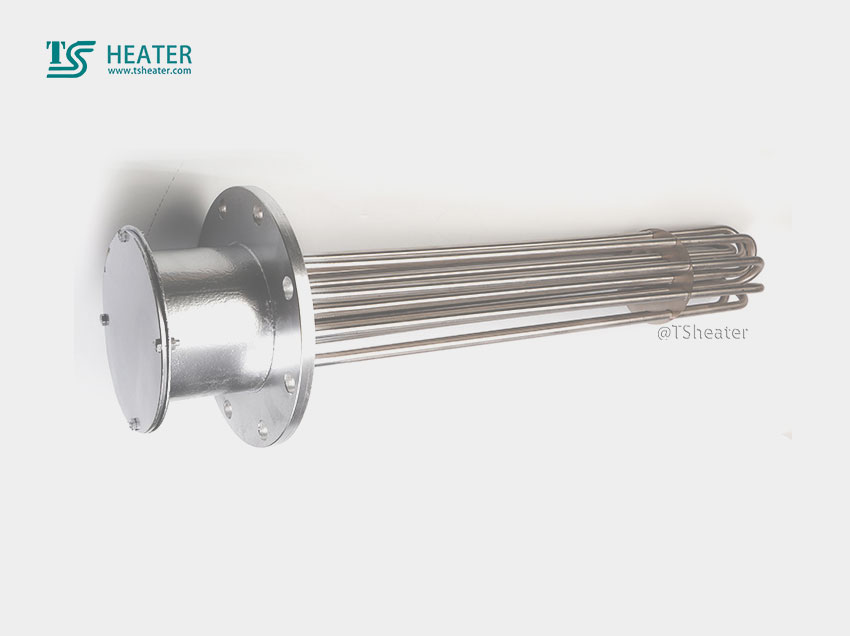

The tubular electric heating element is made of a metal tube (iron, stainless steel, copper, etc.), and the spiral electrothermal alloy wire (nickel-chromium, iron-chromium alloy) is uniformly distributed along the central axis of the tube, and the void-filled compaction has good thermal conductivity and thermal conductivity.Tubular Heating Elements

TS heater

Tubular Heating Elements

Magnesia sand, electric heating elements sealed at both ends of the nozzle with silica gel and treated by other processes. This metal armored heating element heats air, metal molds and various liquids. The utility model has the advantages of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, simple installation and long service life. Applicable to all kinds of saltpet tanks, water tanks, oil tanks, acid and alkali tank heating and fusible metal melting furnaces, air heating furnaces, drying ovens, hot stamping and other devices. Widely used in aviation, shipbuilding, petroleum, chemical, washing, chemical fiber, machinery manufacturing, automotive, electrical, radio, instrumentation, plastics, textiles, food, printing and packaging, rubber, medical and health, household appliances and other industrial sectors. Fourth, the use of precautions:

Tubular Heating Elements

1. Components are allowed to work under the following conditions:

A. The relative humidity of the air is not more than 95%, and there is no explosive or corrosive gas.

B. The working voltage should not be greater than 1.1 times the rated value, and the outer casing should be effectively grounded.

C. Insulation resistance ≥1MΩ Dielectric strength: 2KV/1mi n

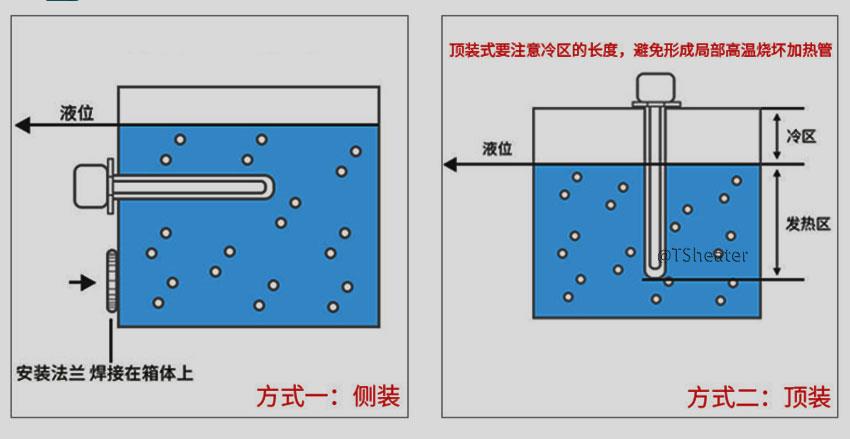

2. The electric heating tube should be positioned and fixed. The effective heating area must be

Tubular Heating Elements completely immersed in liquid or metal solid. It is strictly forbidden to burn. When it is found that there is scale or carbon on the surface of the pipe body, it should be cleaned and reused in time to avoid heat dissipation and shorten the service life.

3. When heating fusible metal or solid nitrate, alkali, bitumen, paraffin, etc., the voltage should be lowered first, and the medium can be raised to the rated voltage after the medium is melted.

4. When heating the air, the components should be evenly arranged, so that the components have good heat dissipation conditions, so that the flowing air can be fully heated.

5. Safety measures should be taken when heating nitrate

Tubular Heating Elements