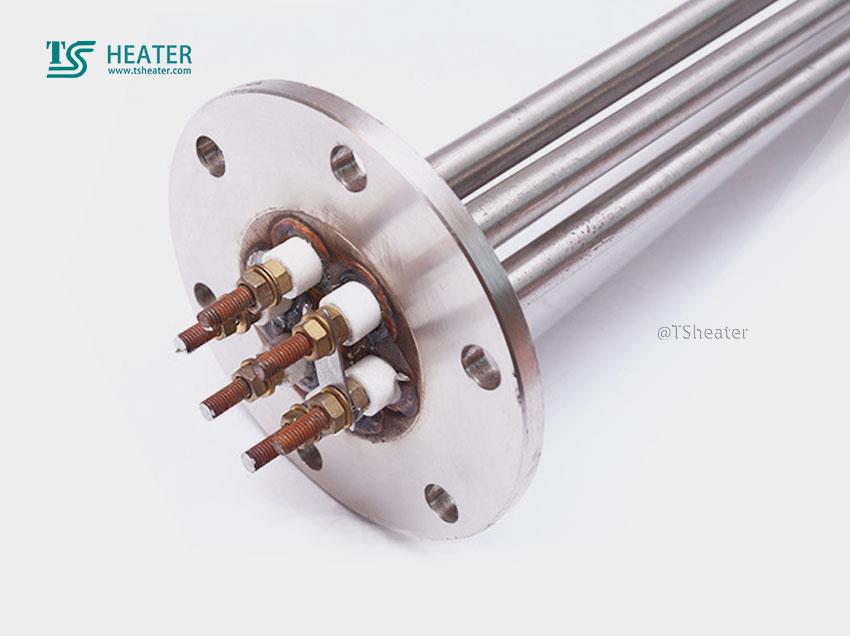

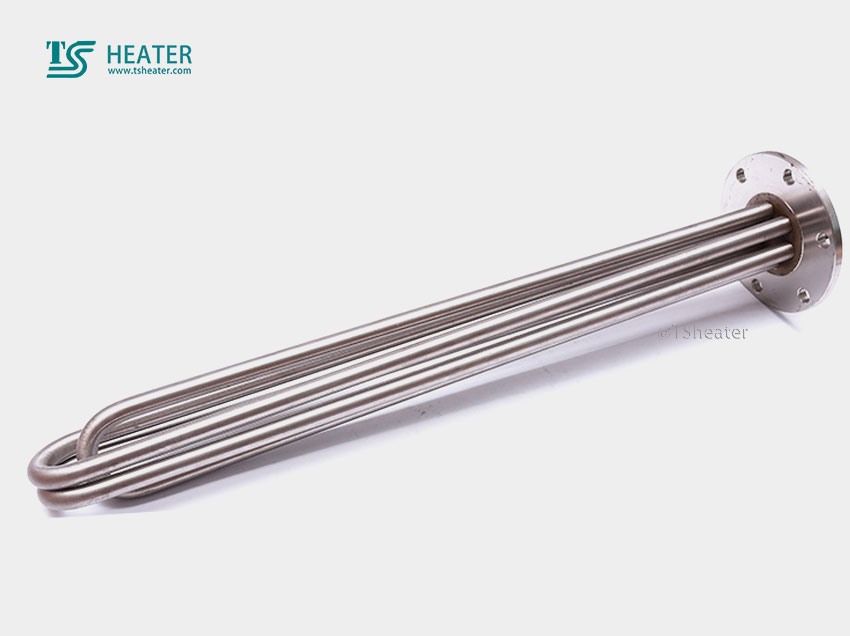

Industrial Submersible Electric Stainless Steel Water Heater Heating Element.water heater heating element.Electric .Austin electric water heater components are made by brazing or welding tube elements to flanges. Hot Water Tubular Heater Immersion Heating Element

General information

Austin electric water heater components are easy to install and maintain.

Submersible heating elements are suitable for liquids and gases in heating vessels and pressure vessels for applications requiring higher kilowatt power.

Austin electric water heater components are made by brazing or welding tube elements to flanges.

The stock flange heater is equipped with a universal terminal housing.

Austin electric water heater components, tubular units, also suitable for small tanks requiring high kilowatt liquid immersion heating.

The unique flat geometry of the tubular element encapsulates more energy in a smaller space and has a lower watt density, making it particularly suitable for petroleum-based liquid heating applications.

Features and performance

Tube diameter, 6 mm - Φ Φ 30 mm

Pipe :SS201, SS304, SS316, SS321, INCOLOY800, etc

Insulation material: adopted

Conductor material: ni-cr alloy resistance wire

Wattage density: high/medium/low (5-25w/cm2)

Lead connection options: threaded stud terminal or lead

Lead wire type :300mm standard (stainless steel water heater with teflon/silicone high temperature glass fiber)

The intensity of heat

No more than 30w/cm2(suggested)

power

Depending on size

Extreme fatigue (when cold)

<= 0.1ma to 242v.

Insulation (cold)

5 min ohm 500 w minimum

Working temperatureUp to :800 degrees

The length of tolerance:+ / - 1.5%

The diameter tolerance:-0.02 to -0.06 mm

Cut off the tolerance:+ / - 15mm

Tolerance (w):+ 5% to 10%

Cold region:Depending on length and diameter 5-25mm

Suggested application

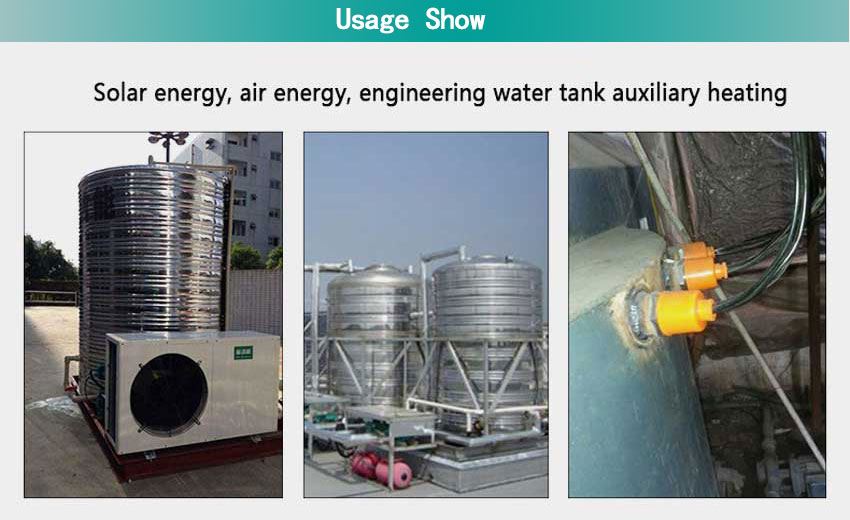

Water deionized, desalted, clean, drinkable, processed

Industrial water rinses the tank

Steam it

Hydraulic oil, crude oil, asphalt

The watt density of the lubricant specified in the API

Air and airflow

Caustic solutions

The chemical bath

Process air equipment

Boiler equipment

Usage Show: