Compared with the traditional heating method, the ceramic heating plate has many advantages such as fast heating speed, good quality of new products, small equipment area, low production cost, and high heating efficiency.

Compared with the traditional heating method, the ceramic heating plate has many advantages such as fast heating speed, good quality of new products, small equipment area, low production cost, and high heating efficiency.

Sometimes a ceramic heating plate is used instead of electric heating, and its power-saving effect is particularly significant. Generally, it can save about 30% of electricity, and it can even reach 60% to 70% in some cases.

application:

1: Widely used in different processing requirements such as heating, melting, drying, shaping, consumption, and curing of many products or materials such as paint, plastic, food, medicine, wood, leather, textiles, tea, tobacco, etc.

2: It is generally believed that the heating and drying of wood, leather, paint, and other organic substances, polymer substances, and water-containing substances has the most significant effect.

3: On some occasions, the effect of this technology and aluminum silicate refractory fiber insulation material in the same furnace is very good.

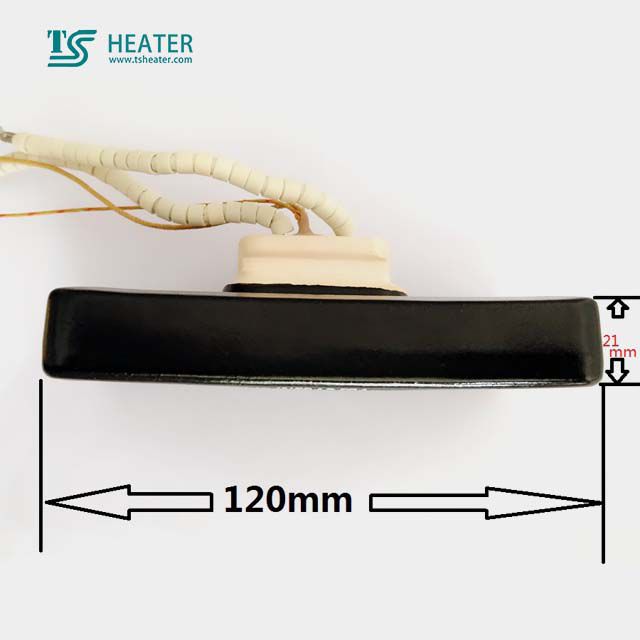

Model: Tablet 60*120

Custom processing: Yes

Type: Ceramic Heating Plate

Surface size: 60*120

Room temperature resistance: 10-55

Power: 500W

Main application: heating of plastic machinery, heating of blow molding machine

Product Certification: CE

Thermocouple: optional

The highest temperature resistance: 450-700

Style: Tablet

Products real shot: