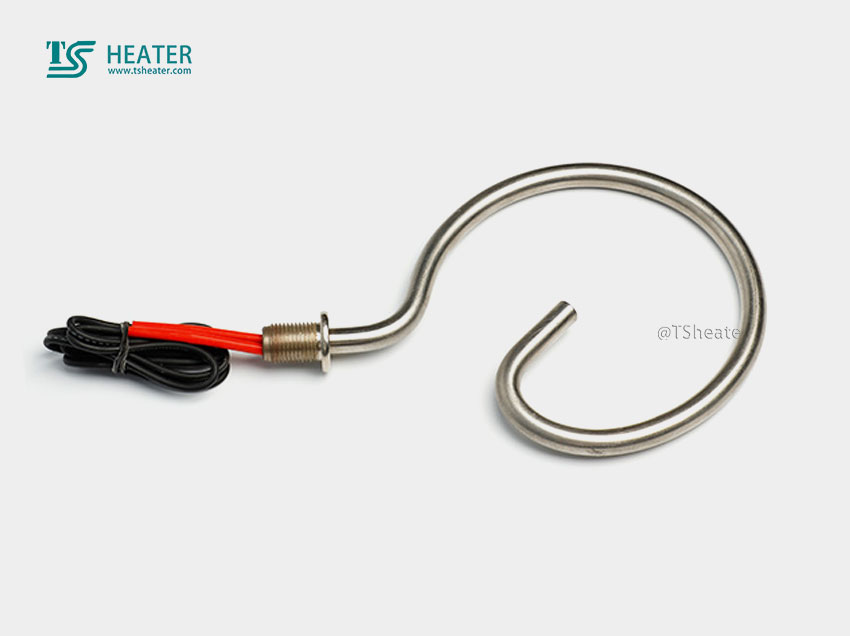

heating element of electric heater.Machine Electric Insertion Cartridge Heater.The box heater manufactured by ts heater is used in many different applications. The high density box heater is molded with an applicable temperature of up to (1100C). Low density box heaters are an economical option for applications requiring lower operating temperatures and power density.Heating Element Of Electric Heater

specification

Heating Element Of Electric Heater

Life is long;

Thermocouple (J or K);

High density;

Mould cone type heater;

Easy to remove;

Diameter 3.0mm to 50mm;

36 volts :12 v, 24 v, 48 v, 110 v, 230 v, 380 v, 450 v

Watts: from 4W to 10KW;

Barrel heater

The box heater manufactured by ts heater is used in many different applications.

The high density box heater is molded with an applicable temperature of up to (1100C).

Low density box heaters are an economical option for applications requiring lower operating temperatures and power density.

tsheater high-density box heater for plastic injection molding has a flat copper end plate that maximizes heat transfer to the probe and bushing gate area.

The structure of the high temperature box heater wound the ni-cr resistance wire precisely on the magnesia core.

Heating Element Of Electric Heater

Insert it into a stainless steel or Pyrex tube and position it on a resistance wire near the sheath.

The core is surrounded by tubes and filled with magnesium oxide powder.

The nickel needle passes through the center of the core and contacts the resistance wire at both ends.

The entire unit is operated in a highly compressed form, ensuring good heat transfer to the outer sheath.

This allows for an operating temperature of 1600°F and a high power density.

One end of the heater is sealed with a welded metal end plate and the other end is drawn out with wire, usually sealed with lava.

A variety of lead and lead protection is available.

Heaters can be supplied with internal thermocouples, mounting accessories and many other options.

Heating Element Of Electric Heater